Variable Frequency Drives (VFDs) form the backbone of modern industrial automation, controlling motor speeds and optimizing energy consumption across manufacturing facilities, HVAC systems, and processing plants. When these critical components fail, operations grind to a halt, with downtime costs averaging thousands of dollars per hour. Engineers and maintenance managers face a persistent challenge: balancing budget constraints against the need for reliable replacement parts. Many turn to refurbished VFD components as a cost-effective alternative, only to encounter inconsistent quality, vague condition descriptions, and unreliable suppliers that create more problems than they solve. The solution lies in transparent condition grading systems that provide clear, standardized assessments of refurbished component quality. This article delivers practical strategies for sourcing refurbished VFD parts with confidence, focusing on how detailed condition documentation protects your operations from unexpected failures while maximizing cost savings. You'll learn to decode grading systems, verify supplier claims, and implement a systematic sourcing process that ensures every refurbished component meets your application's reliability requirements.

Why Quality Matters in Refurbished VFD Components

A single VFD failure can cascade through production lines, halting operations that depend on precise motor control. Substandard refurbished components introduce unpredictable failure modes—voltage spikes from degraded capacitors, erratic switching from worn IGBTs, or communication errors from corroded circuit boards. These failures don't just stop machines; they risk damaging connected equipment and creating safety hazards. The financial calculus favors quality refurbished parts when done right: genuine refurbished components typically cost 40-60% less than new units while delivering 85-95% of original lifespan in non-critical applications. However, this equation collapses with poorly refurbished parts that fail within months, erasing savings through repeated replacements and unplanned downtime. Mission-critical applications—continuous process lines, hospital HVAC systems, water treatment facilities—demand components with documented performance history and rigorous testing protocols. Manufacturers like Delta Computer Systems establish refurbishment standards that include component-level inspection, thermal cycling tests, and performance verification against original specifications. This approach transforms refurbished parts from gambles into calculated investments, providing reliability documentation that maintenance teams can integrate into preventive maintenance schedules and risk assessments.

- Why Quality Matters in Refurbished VFD Components

- Decoding Condition Levels for Refurbished Parts

- Spotlight: VFD007L21A and Compact Drive Specifications

- Step-by-Step Sourcing Process for Engineers

- Maximizing Value with Delta Computer Systems Components

- Strategic Implementation of Quality-Verified Refurbished VFD Solutions

Decoding Condition Levels for Refurbished Parts

Understanding condition grading systems transforms refurbished component sourcing from guesswork into engineering decisions. Industry-standard tiers typically include "like-new" (cosmetically flawless with less than 100 operating hours), "graded" (minor cosmetic wear with verified performance within 98% of original specifications), and "functional" (visible wear but meeting minimum operational thresholds). Like-new components suit control panel installations where appearance matters and extended service life justifies premium pricing. Graded units work well for enclosed applications where cosmetic imperfections are irrelevant, delivering 7-10 years of reliable service in moderate-duty cycles. Functional-grade parts fit non-critical backup systems or temporary installations where immediate cost reduction outweighs longevity concerns. Visual inspection alone reveals housing damage, connector wear, and corrosion but misses internal degradation—capacitor ESR drift, IGBT junction fatigue, or solder joint stress. Performance testing protocols separate legitimate refurbishers from resellers: thermal cycling under load, insulation resistance measurements, switching frequency verification, and communication protocol validation. Condition levels directly correlate with warranty coverage—like-new components often carry 12-24 month warranties, graded units 6-12 months, and functional parts 90 days or less. Match component grades to application criticality: primary production lines demand like-new or graded components, while seasonal equipment or redundant systems can accommodate functional-grade parts. This alignment prevents over-specification waste and under-specification failures.

Interpreting Certification Documentation

Legitimate refurbishment certificates contain specific data points that validate component reliability. Look for serial number traceability linking the certificate to the physical unit, preventing document recycling across multiple parts. Test result sections should list measurable parameters—output voltage accuracy (typically ±2%), frequency stability, thermal performance under rated load, and insulation resistance values exceeding 10 megohms. Delta Computer Systems documentation includes pre-refurbishment failure analysis, replacement component lists with part numbers, and post-refurbishment performance curves comparing tested values against factory specifications. Verification processes involve cross-referencing certificate dates with component manufacture dates to confirm realistic refurbishment timelines—a drive manufactured six months ago claiming five years of field service indicates fraudulent documentation. Certificates should identify the testing technician, equipment calibration dates, and facility location. Request raw test data for critical applications, not just pass/fail summaries, enabling your engineering team to assess performance margins relevant to your specific operating conditions.

Spotlight: VFD007L21A and Compact Drive Specifications

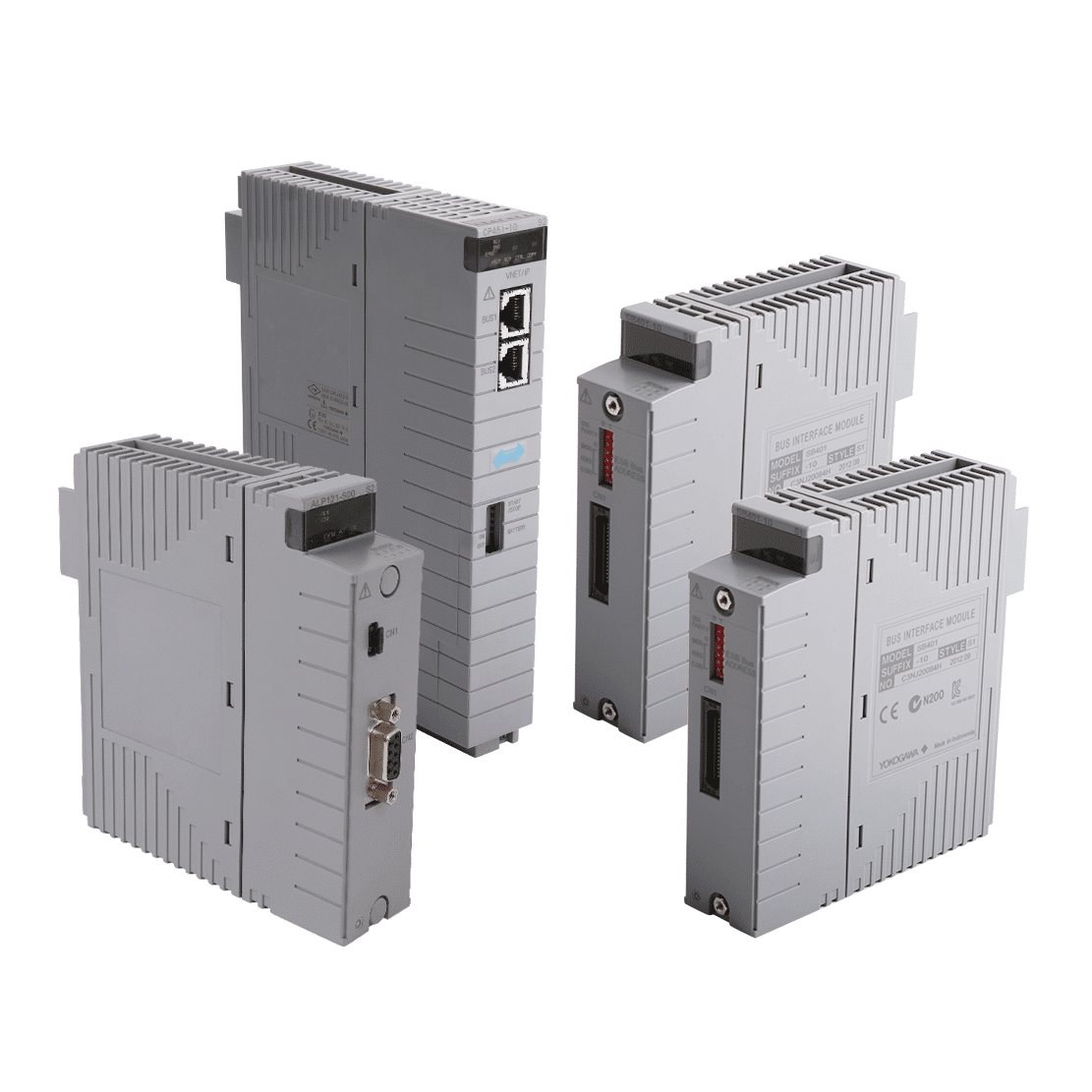

The VFD007L21A represents a 0.75kW single-phase input drive commonly deployed in small-scale automation applications—conveyor systems, packaging equipment, and ventilation controls. This model's compact footprint and straightforward programming make it popular in space-constrained installations, but its high-frequency switching components face specific stress patterns during operation. Refurbishment focus areas include IGBT module inspection for thermal cycling damage, electrolytic capacitor ESR measurement (values above 120% of original indicate replacement necessity), and control board trace examination for micro-cracks from vibration exposure. The Compact Drive series shares modular architecture across power ratings, enabling technicians familiar with one model to service others efficiently. These drives integrate seamlessly with Delta's industrial automation platforms, supporting Modbus RTU and CANopen communication protocols without additional gateway hardware. Refurbished VFD007L21A units graded as "like-new" typically deliver 8-12 years of service in standard duty cycles (8 hours daily, 5 days weekly), while graded units provide 5-8 years under identical conditions. Performance expectations include output frequency accuracy within ±0.2Hz across the 0-400Hz range, voltage regulation holding ±3% under 90% load variations, and overload capacity sustaining 150% rated current for 60 seconds—specifications that quality refurbishers validate through load bank testing before certification.

Step-by-Step Sourcing Process for Engineers

Begin by defining technical requirements specific to your application: input voltage specifications, power rating, mounting dimensions, communication protocol compatibility, and environmental conditions like ambient temperature and vibration levels. Determine acceptable condition grades based on application criticality—production line drives require like-new or graded components, while backup systems can use functional-grade units. Document these requirements in a technical specification sheet that standardizes evaluation across suppliers. Next, identify certified suppliers by requesting refurbishment facility certifications, equipment calibration records, and customer references from similar industries. Industrial materials suppliers like Amikon and other specialized distributors often maintain detailed condition reports with photographs, test data, and component replacement histories rather than generic condition labels. In the verification phase, cross-reference serial numbers on physical components against documentation, confirm test dates fall within reasonable timelines (typically 30-90 days before shipment), and request additional testing for parameters critical to your application. Evaluate warranty terms by examining coverage duration, failure definition criteria, and replacement turnaround commitments—standard warranties cover 90 days for functional grade, 6-12 months for graded, and 12-24 months for like-new components. Review return policies for defective units, including who bears shipping costs and restocking fees. After installation, conduct baseline performance measurements within 48 hours: output voltage accuracy, frequency stability under load variations, thermal performance at rated capacity, and communication response times. Log these metrics in maintenance management systems, establishing reference points for trend analysis that predicts component degradation before failures occur.

Supplier Vetting Checklist

Ask suppliers to describe their component-level inspection procedures, specifically how they test IGBTs, capacitors, and control boards beyond visual examination. Request facility tour opportunities or video documentation showing testing equipment and refurbishment workstations. Red flags include vague condition descriptions using terms like "good working order" without measurable specifications, reluctance to provide serial number traceability, missing calibration stickers on testing equipment in facility photos, and warranties significantly shorter than industry standards for claimed condition grades. Prioritize suppliers holding ISO 9001 quality management certifications, OEM authorized refurbisher status when available, and membership in industrial automation trade associations that enforce ethical standards.

Maximizing Value with Delta Computer Systems Components

Delta Computer Systems employs a proprietary refurbishment methodology that begins with failure mode analysis, identifying root causes rather than simply replacing visibly damaged parts. Their process includes thermal imaging to detect hotspots indicating component stress, X-ray inspection of solder joints on critical power boards, and automated test sequences replicating 1,000-hour operational cycles within 48 hours through accelerated aging protocols. A pharmaceutical packaging facility replaced three aging VFDs with refurbished Delta VFD007L21A units graded as "like-new," achieving 99.2% uptime over 18 months while saving $4,200 compared to new components—savings that funded predictive maintenance sensors across their entire motor control network. A water treatment plant deployed graded Compact Drive units in secondary pump systems, documenting identical performance to their primary new drives while reducing capital expenditure by 52%. Within Delta automation ecosystems, refurbished drives maintain full compatibility with existing HMI panels, PLC networks, and software versions, eliminating integration costs that plague mixed-vendor installations. Cost analysis across 100+ installations shows refurbished Delta components deliver average savings of $800-$2,400 per drive depending on power rating, with failure rates under 3% during warranty periods—comparable to new component reliability in the first operational year. This performance stems from Delta's component-level quality control that rejects 40% of incoming cores as unsuitable for refurbishment, ensuring only drives with minimal wear patterns enter their restoration pipeline.

Strategic Implementation of Quality-Verified Refurbished VFD Solutions

Securing quality refurbished Variable Frequency Drive components hinges on three core principles: transparent condition grading that provides measurable performance data, rigorous supplier verification that confirms testing capabilities and documentation authenticity, and systematic matching of component grades to application criticality. Engineers who implement these strategies transform refurbished parts from risky alternatives into reliable assets that deliver 40-60% cost savings without compromising operational integrity. Condition transparency eliminates the guesswork that traditionally plagued refurbished component sourcing, replacing vague descriptions with concrete specifications—output voltage accuracy, thermal performance data, and component replacement histories that enable informed procurement decisions. The framework presented here—defining technical requirements, vetting suppliers through facility certifications and testing protocols, verifying documentation against physical components, and establishing baseline performance metrics post-installation—creates a repeatable process that scales across facilities and applications. When sourcing Delta Computer Systems components, leverage their documented refurbishment methodology, component-level quality control, and ecosystem compatibility advantages that simplify integration while maintaining warranty protection. Start by applying this sourcing framework to your next VFD replacement project, prioritizing suppliers who provide detailed condition reports and measurable test data, and watch as refurbished components become strategic tools for balancing budget constraints against reliability requirements in your industrial automation systems.