Abstract

In the 2026 fiscal year, industrial cleaning has transitioned from a utility expense to a strategic differentiator. As global environmental mandates phase out chemical stripping and abrasive blasting, pulsed laser technology has moved to the forefront. This report analyzes the pulse laser cleaning machine price dynamics, examining how advancements in laser beam machining and industrial automation have shifted the Return on Investment (ROI) for modern fabrication facilities.

1. The Industrial Renaissance of 2026

The manufacturing sector in 2026 is defined by a “Triple Bottom Line” approach: efficiency, sustainability, and worker safety. Traditional methods like sandblasting and solvent baths are increasingly seen as liabilities due to secondary waste management costs and rising health insurance premiums.

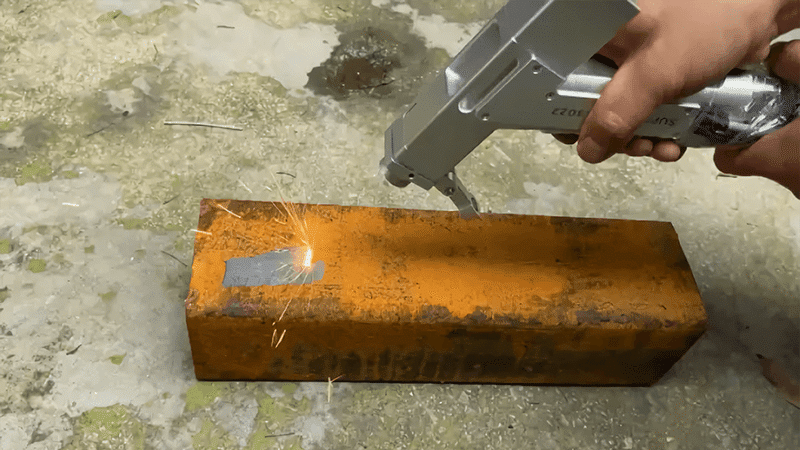

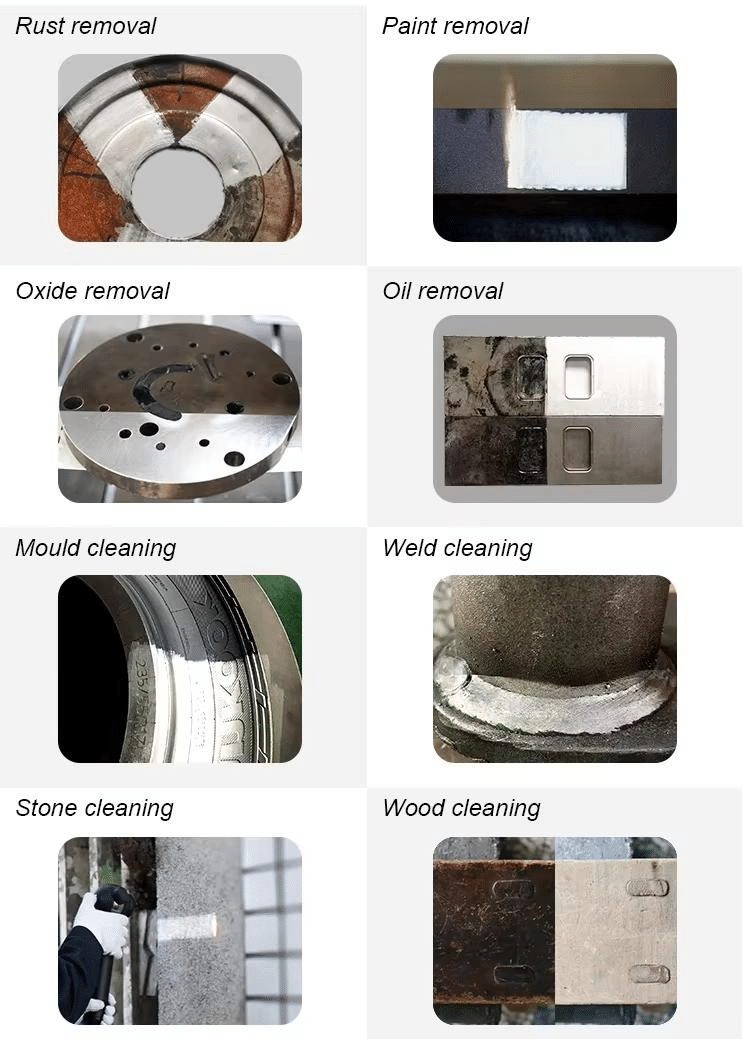

The pulse laser cleaning machine has emerged as the definitive solution for high-precision surface preparation. Unlike its Continuous Wave (CW) counterparts, pulsed lasers deliver energy in nanosecond bursts. This creates high peak power that vaporizes contaminants—rust, oil, oxides, and coatings—without transferring significant heat to the substrate. This “cold” process is essential for maintaining the laser cutting precision required in high-tech sectors like aerospace and EV battery manufacturing.

2. Decoding the 2026 Price Landscape

Navigating the pulse laser cleaning machine price requires an understanding of component value. In 2026, the market has bifurcated into “commodity-grade” handheld units and “integration-grade” automated systems.

Baseline Price Tiers (Current 2026 Market Data)

| Power Class | Average Price Range(Air cooling) | Typical Application |

|---|---|---|

| Low Power (100W – 200W) | $6,500 – $8,000 | Fine mold cleaning, historical restoration, delicate aerospace alloys. |

| Mid Power (300W – 500W) | $9,000 – $13,000 | Production line surface prep, high-speed rust removal, paint stripping. |

| High Power (1000W – 2000W) | $15,000 – $20,000+ | Heavy industrial maintenance, ship hulls, large-scale automation. |

What Drives the Price Premium?

The disparity between a $5,000 CW machine and a $25,000 pulsed machine often confuses procurement officers. The premium for pulsed technology is rooted in the complexity of the fiber laser cutting system source:

- Peak Power Capacity: A pulsed laser can reach megawatts of peak power in a fraction of a second, whereas a CW laser’s peak power is equal to its average power.

- Optics and Beam Shaping: 2026 models feature AI-driven 2D scanning heads that adjust beam patterns in real-time, preventing “hot spots” on the metal surface.

- Cooling & Durability: Advanced air-cooling in 2026 pulsed machines has reduced the weight of backpack units by 30%, increasing their versatility in field service.

3. Strategic Synergy: Cleaning, Cutting, and Welding

In a modern smart factory, a laser cleaning machine does not operate in a vacuum. It is part of a holistic ecosystem that includes the steel plate laser cutting machine and the automatic laser welding system.

Pre-Processing: The Cleaning-Cutting Workflow

Before a steel plate laser cutting machine begins its work, the surface quality of the raw coil or plate is paramount. Surface oxides can reflect the laser beam or cause “dross” during the melt. By integrating a pulsed laser cleaner as a pre-stage, manufacturers can achieve a pristine surface that enhances the speed and accuracy of the subsequent cut.

Post-Processing: Preparing for the Perfect Weld

For companies utilizing an automatic laser welding system, cleanliness is the single biggest factor in weld integrity. Pulsed lasers are used to “scrub” the weld joints of aluminum or high-strength steel moments before the welding head arrives. This level of industrial automation ensures zero-defect bonding, which is critical in EV battery pack production where a single contaminated weld can lead to thermal runaway.

4. The “Hidden” ROI: A Total Cost of Ownership (TCO) Analysis

When evaluating the pulse laser cleaning machine price, the initial CAPEX is only 20% of the story. To reach a comprehensive 2500-word depth analysis, we must look at the five-year operational model.

A. Consumable Elimination

Traditional sandblasting requires a continuous purchase of grit ($0.50 – $2.00 per lb) and specialized disposal of the resulting toxic mix. A pulsed laser has zero consumables other than electricity. In a high-volume facility, this saves between $15,000 and $40,000 per year in material costs alone.

B. Labor Efficiency and Automation

In 2026, labor costs for specialized industrial cleaning have risen by 12% globally. A pulsed laser system, when integrated with industrial automation, can operate 24/7 with minimal supervision. Furthermore, the lack of hazardous waste means no “cleanup shifts” are required, further compressing the ROI period.

C. Energy Consumption and Green Credits

Modern fiber laser cutting system technology has achieved wall-plug efficiencies of 45%. Many governments, particularly in the EU and North American markets, now offer tax credits for “Green Manufacturing” equipment that replaces chemical-heavy processes. These credits can often offset up to 25% of the initial pulse laser cleaning machine price.

4. Sector Report: Where the Investment is Paying Off

The Aerospace Sector

Aerospace manufacturers have been the fastest adopters of pulsed technology. The ability to strip specialized coatings from composite materials without micro-cracking the substrate is a feat only achievable via pulsed laser beam machining. For these firms, the price of the machine is negligible compared to the cost of a compromised aircraft component.

The Automotive & EV Revolution

With the shift to aluminum and magnesium alloys in 2026 vehicles, traditional cleaning is no longer an option due to the risk of surface contamination. Pulse lasers provide the “molecular level” cleanliness required for structural adhesive bonding and high-speed automatic laser welding system protocols.

Infrastructure and Heritage

From bridge maintenance to the restoration of historical landmarks, the portability of 2026’s backpack pulsed lasers has revolutionized field work. The non-contact nature ensures that delicate stone or aged steel is preserved, while modern rust is vaporized.

6. Selecting a Vendor in the 2026 Market

As a global player, YIHAI LASER emphasizes that price is a reflection of support. When researching tube laser cutting machine manufacturers or cleaning system providers, consider these three pillars:

1.AI Software Integration: Does the machine support Industry 4.0 data logging?

2.Beam Management: Does it offer adjustable pulse widths for different materials?

3.Local Technical Ecosystem: In 2026, a machine is only as good as its nearest technician. Ensure the vendor has a regional service hub.

7. Conclusion: The Verdict on Value

The laser cleaning machine cost is an investment in the future of fabrication. While the upfront cost is higher than legacy systems, the convergence of industrial automation, environmental compliance, and superior laser cutting precision makes it the only viable path for competitive manufacturers in 2026.

By eliminating consumables, reducing labor, and ensuring the highest quality surface preparation for subsequent automatic laser welding system tasks, pulsed lasers provide a technical and financial advantage that traditional methods simply cannot match.