Efficiency is not the only factor behind standard forestry operations. Tighter land use requirements, rising safety standards, and environmental awareness have changed how vegetation management is approached. When working across varied terrain and sensitive areas, precision and an understanding of the long-term impact of clearing land sites are required. Equipment selection plays a larger role in shaping forestry workflows as these expectations grow.

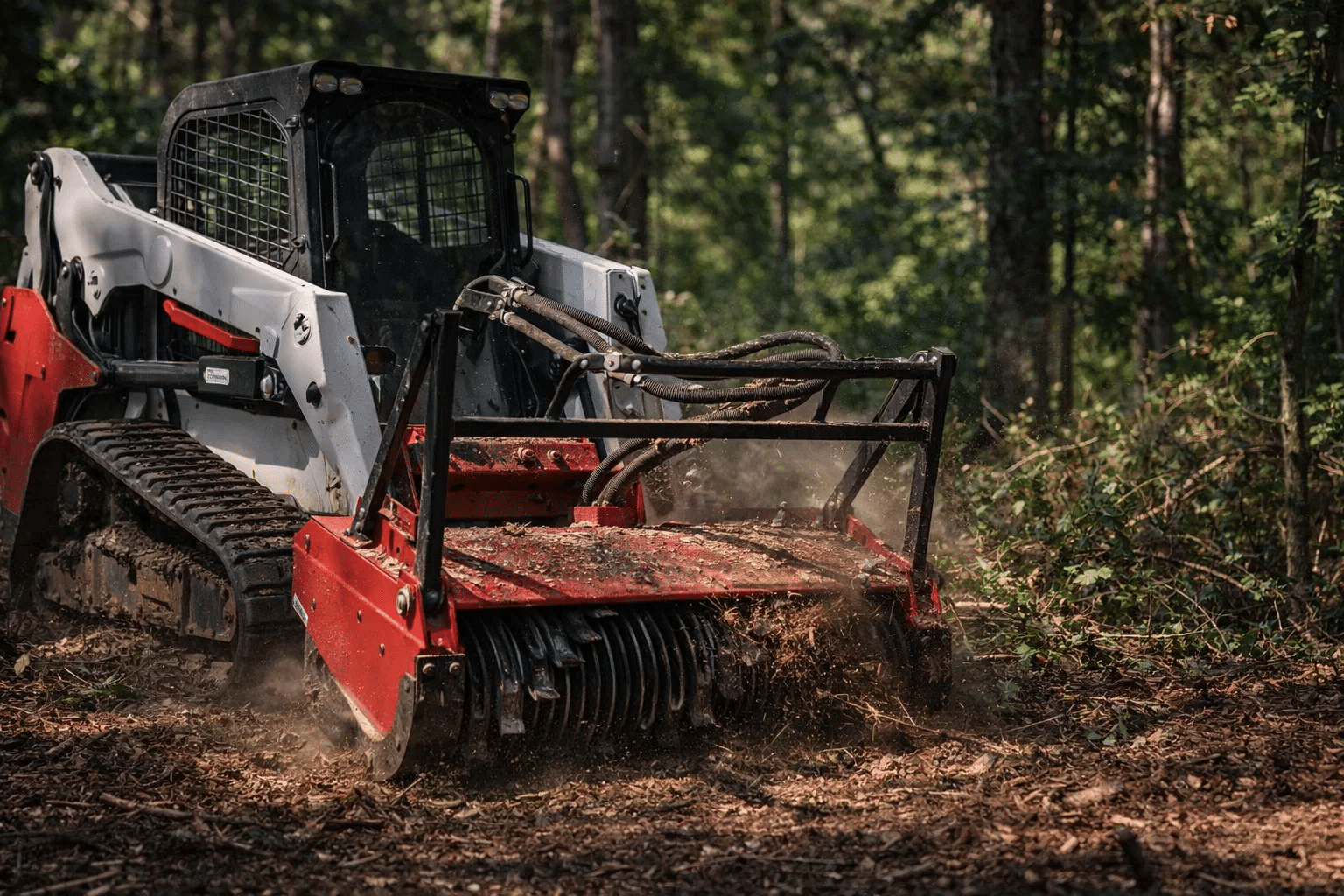

To overcome all these challenges, the forestry skid steer has become a practical choice for vegetation management. A combination of its compact design and the ability to support specialized attachments allows contractors and land managers to operate effectively in spaces where larger equipment may not be suitable.

The Expanding Role of Skid Steers in Forestry Work

Skid steers were once associated primarily with construction and general material handling. Driven by improvements in attachment technology and machine capability, their role has expanded into forestry and land management over time.

Utility corridor, and properties with limited access points where larger equipment may be impractical, their compact size allows operators to work in wooded areas. When paired with forestry-focused attachments, skid steers are commonly used for:

- brush and undergrowth clearing

- selective vegetation removal

- site preparation and routine land maintenance

This adaptability supports a more targeted approach to forestry work, particularly in projects where control and accuracy are essential.

Operational Realities in Forestry Environments

Forestry operations expose equipment and operators to demanding conditions on a consistent basis. Dense growth, uneven terrain, and variable material sizes are common factors that affect both productivity and machine performance.

Complexity got added on with hidden debris, fluctuating soil stability, and extended operating periods. These conditions can accelerate wear and impact reliability over time, which results in critical equipment selection. Durability and operational compatibility are essential for forestry work; machinery designed for predictable environments may not withstand the challenges.

How Experienced Manufacturers Evaluate Forestry Demands

Experience plays a significant role in how forestry equipment is designed. From Fecon’s point of view, long-term exposure to field conditions has highlighted the limits of theoretical performance when machines are used in demanding environments. Forestry attachments must handle sustained contact with dense material while maintaining control and efficiency throughout extended work cycles.

This practical focus often leads manufacturers to prioritize elements such as:

- smooth and consistent material processing

- durability under repeated impact

- balanced load distribution to reduce machine strain

For example, Fecon’s Bull Hog mulching attachments follow this design philosophy. Built for vegetation management applications, they are intended to operate with skid steers across multiple power classes, placing greater emphasis on reliability and consistency than on short-term performance metrics.

Practical Considerations When Selecting Forestry Attachments

Choosing a forestry attachment involves more than matching it to a machine. Operators often begin with hydraulic compatibility, knowing that mismatched flow or pressure can affect performance and safety over time.

From there, practical jobsite factors usually come into play, including the type of vegetation, terrain stability, and how easily the attachment can be serviced. A forestry skid steer setup is selected with long-term use in mind for many professionals. Dependability, parts access, and service support often matter just as much as how the attachment performs on day one.

Operator Efficiency and Site-Level Control

The equipment performs well in complex working environments, which directly reflects the operator’s efficiency in forestry applications. Machines with compact design allow precise positioning, minimize site disturbance while supporting reliable productivity across different terrain types.

Skid steers are often selected for their maneuverability and clear sightlines when working near obstacles or in sensitive areas. When used with forestry-focused attachments, this level of control supports targeted vegetation management. For land managers considering long-term outcomes, precision and adaptability frequently outweigh short-term production gains.

Looking Ahead in Modern Forestry Operations

Forestry work is moving toward approaches that balance efficiency with environmental responsibility and operator safety. This shift is influencing how equipment is selected and how vegetation management projects are planned.

This evolution of forestry skid steer is like an opportunity for manufacturers like Fecon, which designs equipment that reflects real-world use. Modern forestry operations have skid steers matched with forestry-specific attachments, helping land managers adapt to changing site conditions and long-term management goals.