Quilt claims to have solved the most difficult aspect of multi-zone heat pumps: remaining efficient and stable when demand is low. The start-up’s new three-zone mini-split purrs its compressor along with so little power that it earns near-full capacity anytime it gets into deep cold, aiming for the trade-off alchemists have tried to forge for years.

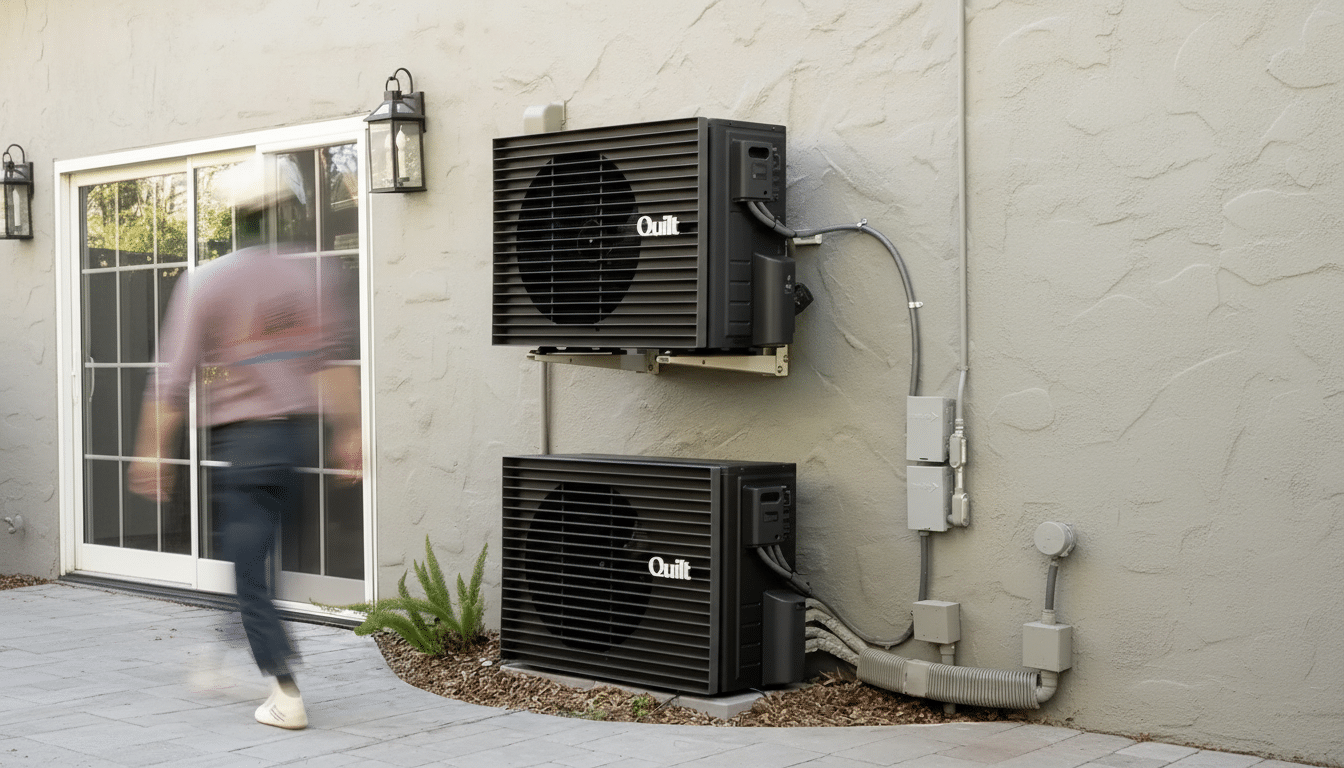

The configurations connect one outdoor unit with three indoor heads, reducing installation complexity and the backyard footprint. It is another first as the company builds Quilt’s fleetwide data strategy into a flagship product, with a side of new capital to help fund it: A $20 million Series B to scale up sales.

- Why low-load performance challenges multi-zone heat pumps

- How data-driven engineering shaped Quilt’s new system

- Bending the performance curve with smarter heat pump hardware

- Why it matters for homes and the grid, and energy bills

- A concrete home use case showing low-load stability benefits

- What to watch as independent testing and pilots arrive

Why low-load performance challenges multi-zone heat pumps

Heat pumps’ ability to match output to need is what makes heat pumps efficient, which is made possible thanks to variable-speed compressors. At extremely low speeds, however, even the best compressors can grow unstable and difficult to control (with oscillations, short-cycling and comfort swings that result). Most multi-zone systems sidestep the decision by either turning off the compressor below a certain point or dumping additional heat, in ways that drag on efficiency and comfort inside.

That behavior is most pronounced during shoulder periods and in the evenings, when only a modest room needs conditioning. That’s because ratings based on standard loads, such as those in the AHRI 210/240 process, don’t take into account these granular low-load real-world situations. The result: homeowners generally buy a “high-efficiency” unit, which makes it possible for the heating or cooling system to idle inefficiently when the house requires only a trickle of conditioning.

How data-driven engineering shaped Quilt’s new system

Quilt infused its units with denser sensing than your normal mini-split and sent that data up to the cloud. That telemetry — encapsulating about a thousand deployed systems over diverse climates — fed control algorithms that learned from real usage, rather than a few lab profiles. The dividend has been fast iteration in the field.

For instance, Quilt sent out an over-the-air update that unlocked 20% more capacity for one or two zones during heat waves or cold snaps. Such fleetwide tuning, based on real-world data feedback, laid a crucial foundation for the new model’s biggest trick: stable, precise modulation even under extremely low loads without sacrificing cold-weather punch.

Bending the performance curve with smarter heat pump hardware

Quilt pairs an over-performing copper coil with an undersized compressor to increase turndown and get better heat exchange at low mass flow. The three-zone unit, the company says, can still deliver 90% of its rated 27,000 BTU cooling capacity at -13° F (-25° C), a figure that’s usually only applicable to single-zone systems designed for cold climates — illustrating just how subtly it idles when there’s almost no work to do.

Every indoor head can be operated independently for as little as 2,100 BTU of heat or 1,400 BTU of cooling. When a zone isn’t calling, refrigerant continues to flow, but the outdoor unit emits only about 300 BTU of waste heat — roughly equivalent to a person’s output — so “ghost heating” of adjacent rooms is minimized. Quilt is the first to place the unit as the most advanced three-zone mini-split on the market.

Why it matters for homes and the grid, and energy bills

For homeowners, more precise low-load control leads to steadier temperatures, quieter system operation and enhanced dehumidification. It also reduces the stop-start cycling that wears components and inflates bills. Space heating typically is the largest home end use, notes the U.S. Energy Information Administration, so even relatively small efficiencies at commonplace low-load operating conditions can translate into real savings.

Decarbonization is crucial in all cold-climate parts of the world. Cold-climate specifications and utility incentives have driven the market toward heat pumps that retain capacity in sub-freezing temperatures. The International Energy Agency reports continued double-digit growth in global heat pump sales over the last several years; designs that still perform efficiently in mild (and frigid) weather help drive adoption faster and take some of the edge off times of need for grids.

A concrete home use case showing low-load stability benefits

Imagine a three-bedroom home on a crisp spring night: The living space is comfortable, one bedroom wants to take the edge off a little chill and another is set cooler for sleeping. On a lightly loaded system, traditional multi-zone systems will oftentimes overshoot or short cycle. Quilt’s finely divided near-minimum level of power allows the calling bedroom to experience a whisper of warmth while the others continue in steady state, and the outdoor unit loafs along nicely instead of ramping up and down constantly.

In winter months the same system used for cooling can heat a family room during a polar outbreak at near full rated capacity, eliminating need for backup resistance heat. The combination of high turndown at low loads and high capacity in deep cold strikes directly at the central trade-off of the category.

What to watch as independent testing and pilots arrive

Quilt’s great claims will be independently listed by AHRI and cold-climate programs that verify its capacity retention and minimum usable outputs across zones. If those figures bear out in third-party data and utility pilots, look for more multi-zone systems to pursue similar architectures and software strategies.

Quilt makes software for AR sound less like an afterthought on a tight budget than something that engineering departments can take ownership of and own the technical lead on.

The company is quiet about its roadmap, but this much is clear: use field data to iterate controls and customize hardware around real-world edge cases. In a segment in which the main struggle has been at the low end of the curve, solving for low load without sacrificing cold-weather muscle is a step ahead.