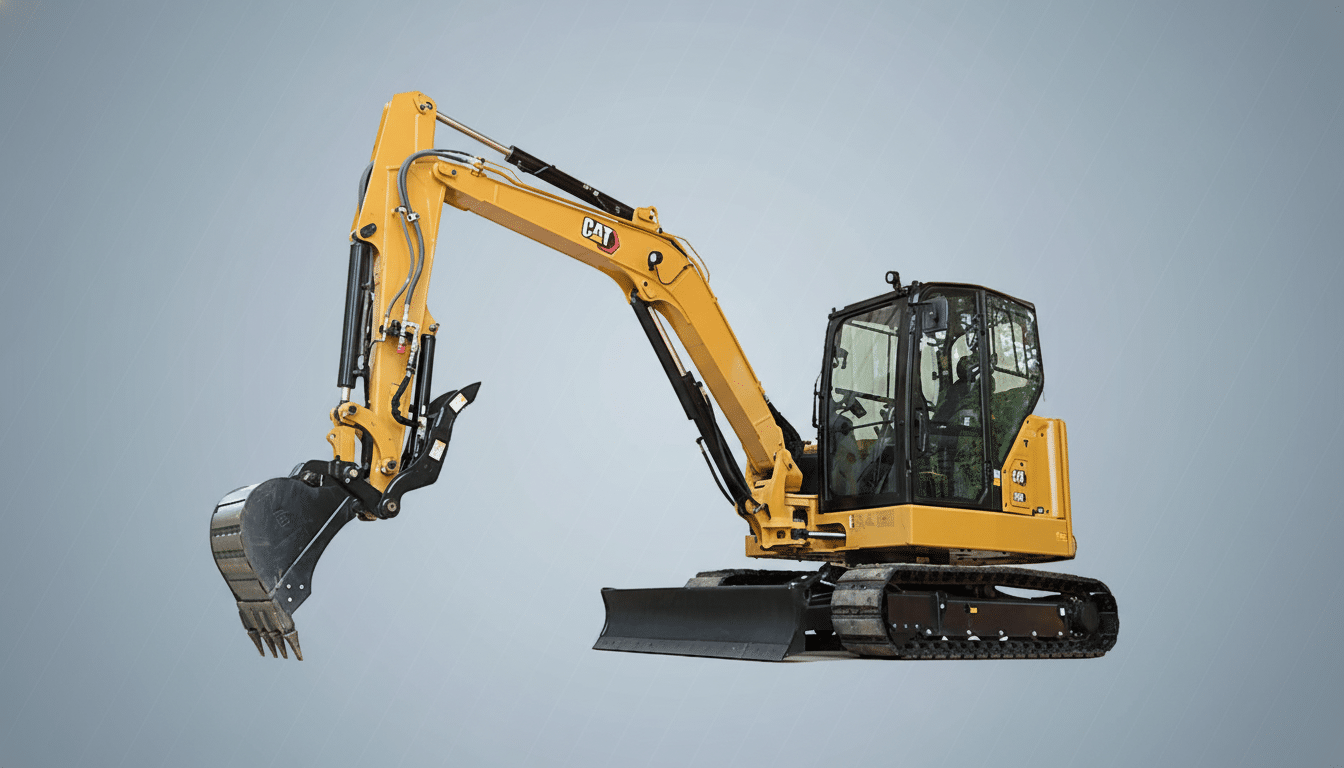

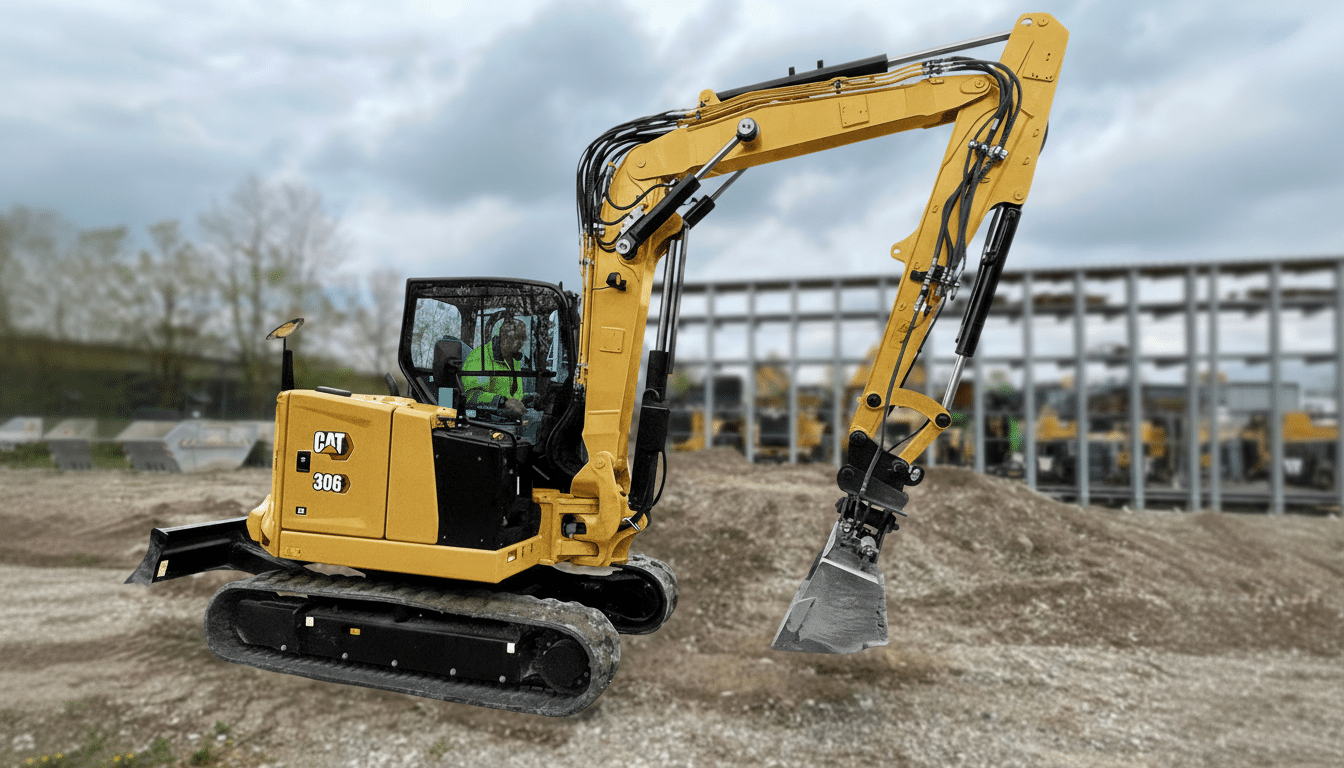

Caterpillar is taking AI from the lab to the jobsite by embedding “Cat AI” in its construction equipment, thanks to Nvidia. The first pilot is on the mid-size Cat 306 CR Mini Excavator, using Nvidia’s Jetson Thor platform to enable real-time perception and assistive capabilities. The system is being showcased at CES, marking an effort to make heavy iron smarter, safer and more productive, without transforming the way crews work.

What Cat AI Does on the Jobsite: Assistive Capabilities

Cat AI is intended as an operator assist, not a complete autonomous substitute. Think of it as a co-pilot: Onboard sensors and edge computing take on the work of object detection, path guidance and precision digging aids, while the human operator remains in charge. Powered by Jetson Thor, the excavator can also meld camera and machine data to flag hazards, steady the bucket however many inches from the target grade — particularly helpful for younger operators who are fast but not as precise as veterans.

The core benefit is immediacy. Caterpillar stressed that insights come where work is performed — in the cab and in the dirt — and not on a dashboard after the fact. By keeping inference on the machine and sending only summaries to the back office, crews can make decisions in seconds, instead of searching hours later through logs.

Digital Twins and Data as the New Payload

Assistive features, however, conceal a firehose of telemetry. Caterpillar says its connected machines send about 2,000 messages per second. Those signals feed Nvidia’s own Omniverse ecosystem and are used to construct digital twins of active jobsites, which teams can use to simulate schedules, test haul routes and estimate materials before investing resources on the ground.

That’s important, because the productivity gap in construction continues to be sticky. The McKinsey Global Institute has long observed that construction productivity has grown by about 1 percent a year over decades, as against roughly 2.8 percent in the broader economy. Small declines in cycle time, rework and idle fuel burn can make or break project margins. Digital twins can run sequence and crew allocation through their paces, while Cat AI ensures that the operator in the field is performing plan-based work accurately.

The same data loop reinforces safety. Proximity alerts and automatic intervention around people, poles and other obstructions can help minimize “struck-by” incidents — one of the five leading causes of jobsite fatalities named by OSHA — while detailed post-run analytics allow managers to adjust site layouts and traffic flow before issues repeat.

Nvidia’s Physical AI Push Collides With Caterpillar’s Autonomy Track

Nvidia is setting up an end-to-end approach to “physical AI” that includes open models, such as its Cosmos family; simulation tools such as Omniverse; and deployment hardware including Jetson Thor. The plan would be to train and validate the AI in photorealistic simulation, then deploy those same models on ruggedized edge computers embedded within robots and heavy machinery.

For Caterpillar, this is hardly cold-starting. The company already has fully autonomous haul trucks operating in mining, where environmental control and predictable paths play to autonomy at scale. Construction is dirtier — dynamic sites, mixed fleets and varied terrain — so assistive AI logically follows the path from guidance to supervised automation and, ultimately, task-level autonomy.

That competitive landscape is getting hotter. Rivals across yellow iron — from Komatsu and Volvo CE to Deere — are embedding advanced operator assistance, grade control, and site management analytics. And if Caterpillar can standardize it across its portfolio, the integration of a compute platform and digital twin pipeline that runs from design to deployment could be a competitive differentiator.

Why This Might Change Jobsite Economics

Contractors don’t purchase AI; they buy results. Bank on Caterpillar measuring Cat AI in real metrics: cycle time reduction per pass, fuel savings during idle and swing, fewer rework events and fewer incident rates. Ninety-four percent of the time, it’s about avoiding rework. Studies conducted by the Construction Industry Institute have associated rework with significant portions of project cost, and reducing even a sliver through better guidance and planning amounts to real dollars.

Adoption will depend on practicality just as much as performance. Simple retrofits, compatibility with mixed fleets and easy training will decide whether contractors deploy assistive AI beyond pilot machines. Industry organizations like the Association of Equipment Manufacturers cite increasing telematics and machine control usage; on-machine AI becomes a logical extension if it integrates with familiar workflows and overarching data environments.

The near-term road map probably remains focused on assistive add-ons, more models trained in Omniverse and expansion to loaders, dozers and articulated trucks. If the results hold — faster and safer cycles, plus more precise planning — Caterpillar’s Nvidia hookup could be one of those turning points where physical AI goes from optional extras you pay a premium for to standard kit across construction equipment.