Material handling may seem like a continuous struggle. Workers experience heavy lifting, irregular workflow, and delays that reduce production.

Movement of materials manually raises the risk of mistakes and injuries in the workplace, and also takes up precious time and labor. These issues complicate the operations in terms of efficiency and production goals.

The answer is in automation, which is conveyor systems to facilitate goods movement, decrease manual input, and boost operational efficiency. With the integration of these systems, facilities are guaranteed a more fluid material flow and increased productivity.

This article examines six reasons why conveyor systems are important in enhancing the handling of materials in an industrial environment.

1. Boost Operational Efficiency

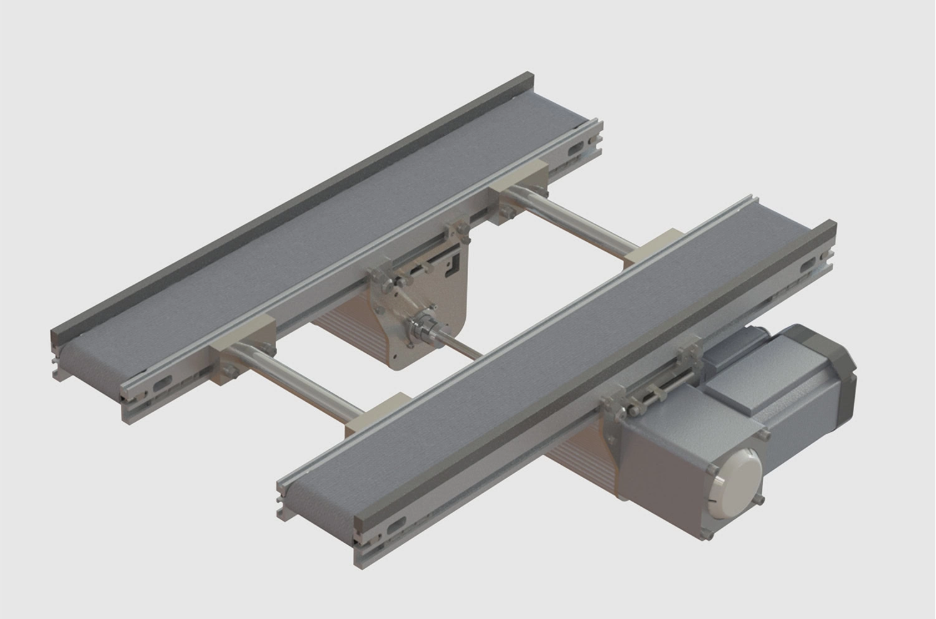

Roller Conveyors have a direct effect on operational efficiency by automating the transport of materials across each production floor. Instead of relying on manual handling or forklifts, items move smoothly along the roller paths in a continuous flow, significantly reducing bottlenecks and improving overall productivity.

This smooth movement helps to deliver materials to each production phase in time and avoid unnecessary delays. Besides, modular conveyor layouts enable convenient changes to suit fluctuating production needs to ensure the optimum workflow.

In industries that have heavy or bulky products, the belt conveyors ensure a consistent flow without the need for extra labor, reducing downtime and maximizing throughput. A steady pace means that operations can continue to process larger volumes without the need to increase the workforce and effort.

2. Reduce Labor Costs

Incorporation of conveyor systems minimizes the use of manual labor in handling materials. Workers do not have to transport, push, and drag heavy items over many distances, and this reduces physical strain and fatigue.

As a result, repetitive tasks need fewer workers, and the management can use the manpower to assign them to more competent opportunities. Also, less manual handling minimizes the chances of human error, where products are moved in the right direction and with efficiency.

In the long run, the labor cost savings and decreased claims of injuries give quantifiable financial gains. Automated conveyors ensure uniformity during shifts, and they help facilities to produce more output using fewer resources, which ultimately results in more cost efficiency.

3. Enhance Workplace Safety

One of the top causes of workplace injuries in the industrial setting is manual handling. Conveyor systems reduce this risk since materials are moved without the employee being required to carry heavy loads.

Additional features such as regulated speed, safety measures, and ergonomic designs also help to safeguard workers against accidents. Moreover, conveyor configurations can be customized and are always modular to create a secure traffic path for materials, minimizing clutter and the risk of production flooring.

Employees are also able to engage in activities that demand skills rather than exertion due to reduced physical strain and fewer chances of injury. Such enhancement of safety not only maintains the health of the workforce but also helps to keep the regulatory compliance and operational stability.

4. Improve Space Utilization

Efficient material handling depends on how well the floor space is optimized, and conveyor systems are the best at it. They can be designed to conform to intricate designs, fit in narrow spaces, and even operate vertically to move products between levels.

Such flexibility enables the companies to utilize the areas better without expanding the facilities. Conveyors eliminate the large aisles, storage areas, and manual points of transfer by consolidating movement along fixed routes.

Modular systems are also flexible to changes in the future, with the business capable of reorganizing layouts as production requirements vary. Efficient use of space leads to streamlined working processes, quick availability of materials, and more orderly production facilities.

5. Maintain Consistent Product Flow

Inconsistent material flow can disrupt production schedules, create bottlenecks, and increase processing time. Conveyor systems ensure the continuous and predictable movement of products across every stage of operation.

This reliability allows downstream processes to receive materials precisely when needed, reducing waiting periods and idle time. Advanced belt and roller conveyors accommodate a wide variety of product shapes, sizes, and weights, ensuring smooth transport even for delicate or heavy items.

With automated flow, production lines maintain steady output without interruptions, improving both efficiency and product quality. Additionally, conveyors can be integrated with sensors and monitoring systems to track throughput in real time, allowing managers to make data-driven adjustments and maintain seamless operations at all times.

6. Enable Scalability and Flexibility

One of the strongest advantages of conveyor systems is their ability to scale with operational growth. Modular conveyor solutions can be extended, rearranged, or integrated with additional equipment to match evolving production demands.

This flexibility allows businesses to adjust throughput without completely overhauling existing setups. Whether expanding production lines or adding new stations, conveyors provide a foundation for long-term adaptability.

Furthermore, modular designs allow integration with automation technologies, sensors, and custom accessories, offering tailored solutions for specific material handling requirements. As a result, facilities can grow efficiently while maintaining smooth operations and minimal disruption.

Conclusion

Conveyor systems offer practical solutions to the common challenges of material handling, transforming labor-intensive processes into efficient, automated workflows.

By improving operational efficiency, reducing labor costs, enhancing safety, optimizing space, ensuring consistent product flow, and supporting scalability, conveyors create a streamlined environment that benefits both workers and businesses.

Their modular and versatile design allows easy adaptation to evolving production needs, making them an essential investment for modern industrial operations. Incorporating these systems enables facilities to achieve higher productivity, lower risk, and better overall control of material movement, establishing a more reliable and effective production infrastructure.