Samsung’s Galaxy Z TriFold has hit a significant early benchmark in public stress testing — it survived 25,000 open-and-close cycles during a duo of live streams by South Korean channel OMG_electronics.

That’s still only a fraction of the manufacturer’s 200,000-fold claim, but the device’s display and its hinges have remained unscathed — giving us an incredibly rare real-world look at how a triple-panel foldable behaves when subjected to sustained mechanical torture.

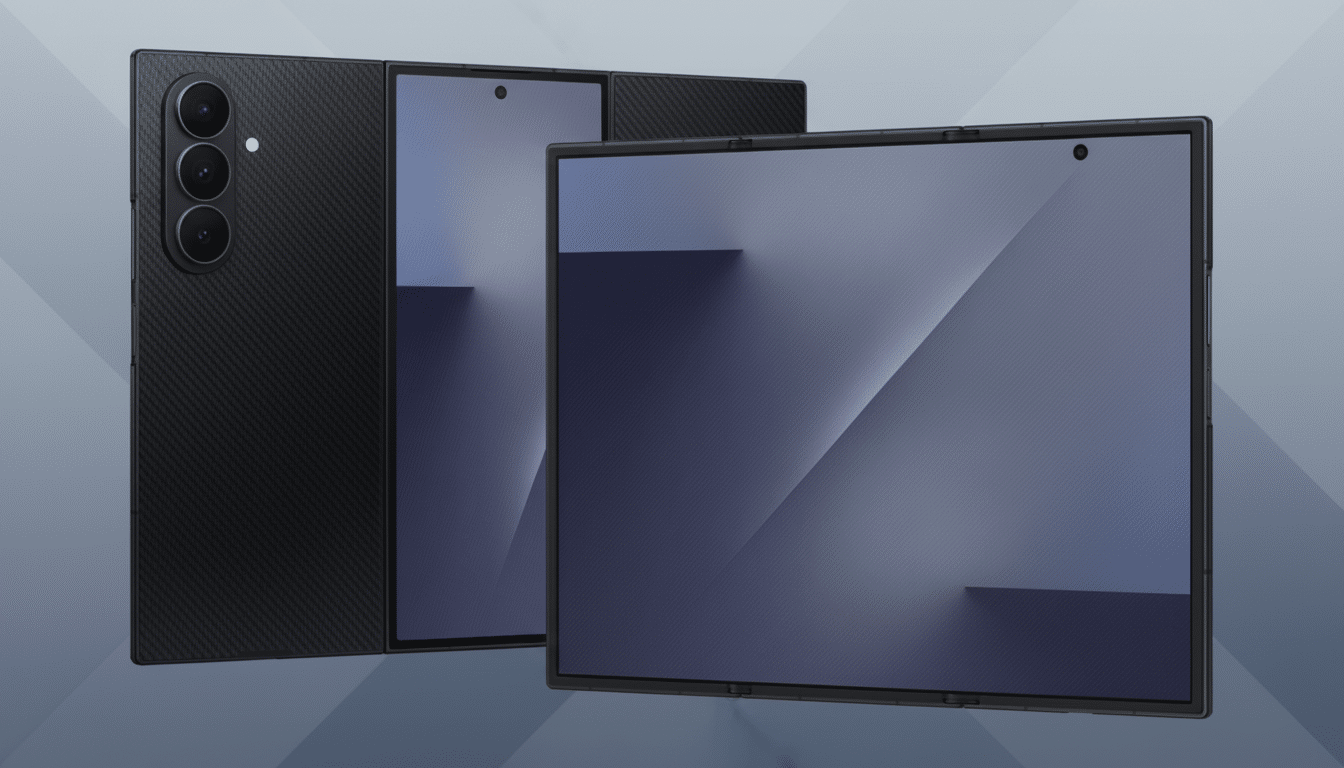

First glimpse at real-world durability under live testing

Samsung rates the TriFold for 200,000 folds, a number determined as an approximation of about one hundred cycles per day over five years under controlled circumstances. 25,000 cycles is 12.5% of that goal — about eight months of average use run into a marathon. The endurance numbers may sound like a dry factoid to base your purchasing decision on, but the speed at which it’s folded and unfolded, and its environment, matter: quick, successive folding heats up hinge parts and stresses adhesives that hold those parts together, increasing wear on an ultra-thin glass screen (and other protective films) compared with standard use over several hours or days.

For a design like the tri-fold, durability is a two-front war. It comes down to this: two hinges must stay in concert as they open and close, keep three screen sections properly aligned, and stop torsion from focusing at the middle crease. However, the lack of immediate failures at 25K cycles means that hinge geometry and the layer stack are somehow managing early-stage mechanical fatigue.

How the endurance marathon was run and measured

Testers opened and closed the TriFold by hand, recording cycles over two sessions. The first stream clocked in at around six hours and over 9,000 folds; a second session got the total to 25,000 after about another 10 hours. That’s an average of nearly 1,560 cycles per hour — roughly a fold every two to three seconds — which is much more abuse than typical daily wear and tear.

To ensure the count was above board, they mounted pressure sensors at each hinge to record an event whenever the mechanism hit its stops. On a device with dual hinges, independent sensing allows the machine to capture miscounts due to partial folds or inconsistent movement and can signal asymmetry if one hinge starts losing torque before the other.

Lessons from past trials and community tests of foldables

Previous foldables were stress-tested by the community, for useful context. A previous public fold test ended at 200,000 cycles and did not end because of the flexible display breaking, but with other hardware degradation on a Galaxy Z Fold model — the speaker in particular. Independent drop and durability programs, like the one from Allstate Protection Plans, have tested foldables over and over; they outlast drops by folding a lot more than they thrive in sudden-impact tests, highlighting that hinge durability is different from the ability to withstand drops.

Common wear points to monitor as counts climb, Apple says, include:

- Hinge stiffness drift

- Alignment creep (panels no longer sit perfectly flush)

- An increase in crease visibility under bright lighting

- Any lifting in the protective film near stress concentrators

What to watch as the fold count rises toward 200,000

Closing in on 200K, veterans of teardowns like iFixit tend to keep an eye on three markers: hinge torque retention, resistance to particulates, and the integrity of the display layer. Repetitive folding may also heat up the hinge, trapping oil and enabling more dust to enter as tolerances open. On the panel surface, repeated bending strains both the ultra-thin glass and polymer layers, particularly in the vicinity of the crease’s neutral axis, increasing the potential for micro-marring or film lift.

For the TriFold in particular, its dual-hinge synchronization is a point of distinction. If one hinge starts to come loose before the other, users could feel a “step” when unfolding or see different gaps. Two hinges also double the probability of long-term rattle and increase the likelihood that even a slight misalignment can lead to visual artifacts across both halves of the display.

Implications for buyers weighing durability and price

If the TriFold soldiers well north of 25K cycles without panel or hinge issues, it will be further evidence that triple-panel designs are maturing beyond a sort of concept status. And that matters for early adopters who are weighing high prices and limited availability against longevity. Enterprise buyers, who typically shoot for three-year replacement windows, will be monitoring to see if hinge torque and display integrity are consistent well beyond 100K (because that’s when daily business use starts to matter).

It’s also important to keep in mind that a public test is one data point under abnormal conditions. Manufacturer claims are obtained from larger test mats with temperature, humidity, and particulate controls. But community stress tests do offer some honest counterpoint: if a device survives that kind of continuous abuse on camera, there’s a good chance it will meet — or exceed — expectations in everyday life.

For now, 25,000 cycles is a hopeful milestone. The larger question is whether the TriFold holds together mechanically as the count grows — with no creeping hinges, rising creases, or accessory failures. If it does, the device will not just meet a spec sheet number; it will show the practical reliability that foldable skeptics have been waiting to see.