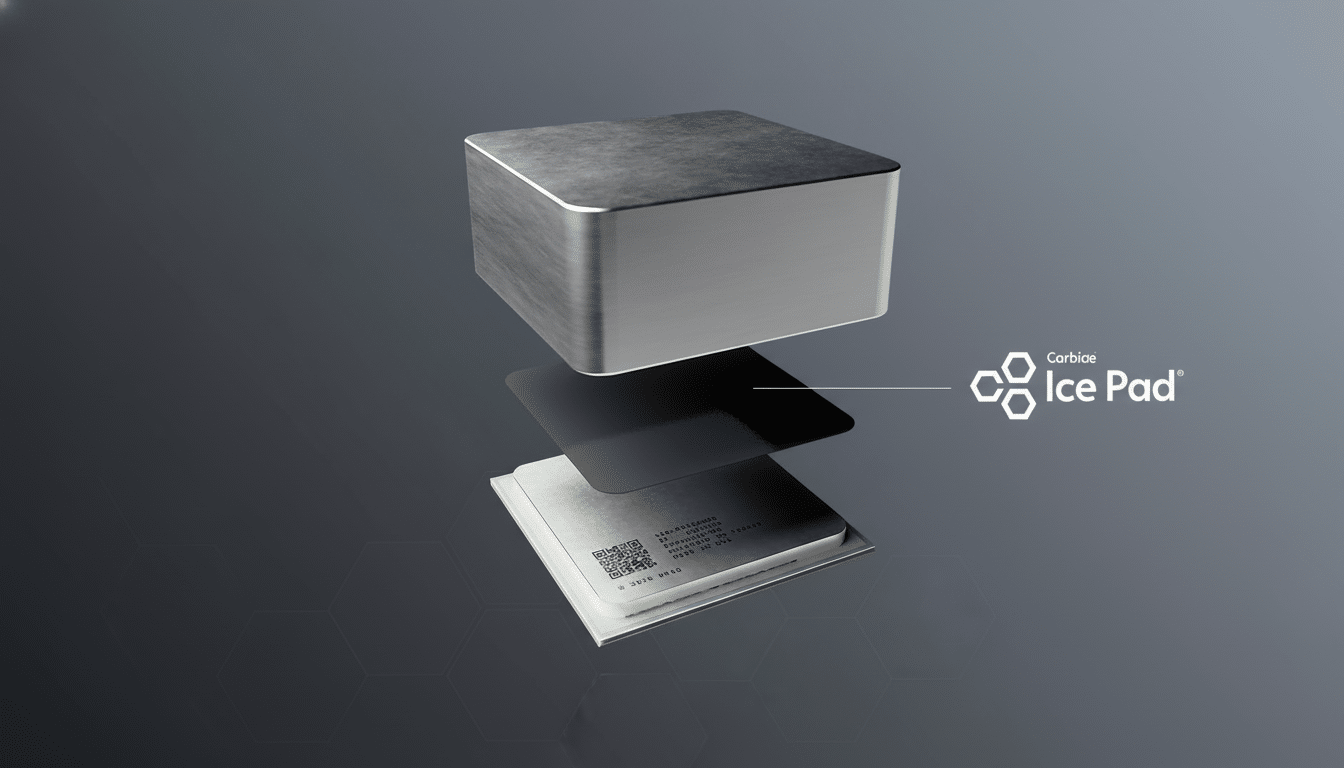

A thermal interface material startup is betting on carbon nanotubes for the next big leap in CPU cooling. At CES, Carbice introduced its Ice Pad, a solid-state thermal pad composed of stacked layers of carbon nanotubes and featuring an embedded aluminum sheet—promising lifetime durability and leading heat transfer without the paste-related mess or maintenance.

What Carbice is showing: Ice Pad design and conductivity details

The entire CPU heat spreader is covered by the Ice Pad, with dual carbon nanotube (CNT) layers and a thin aluminum core for effective heat dissipation from hot spots. Carbice is advertising in-plane thermal conductivity of up to 200 W/mK, a figure that’s bound to make a splash in a market where most available pads and pastes are often down by an order of magnitude.

- What Carbice is showing: Ice Pad design and conductivity details

- How CNT pads differ from thermal pastes in real use

- Longevity claims and why they could matter for PCs

- Key performance questions the community will ask first

- Electrical safety considerations and installation guidance

- Why OEMs will adopt CNT pads first for consistent builds

- Bottom line and what PC builders and buyers should watch

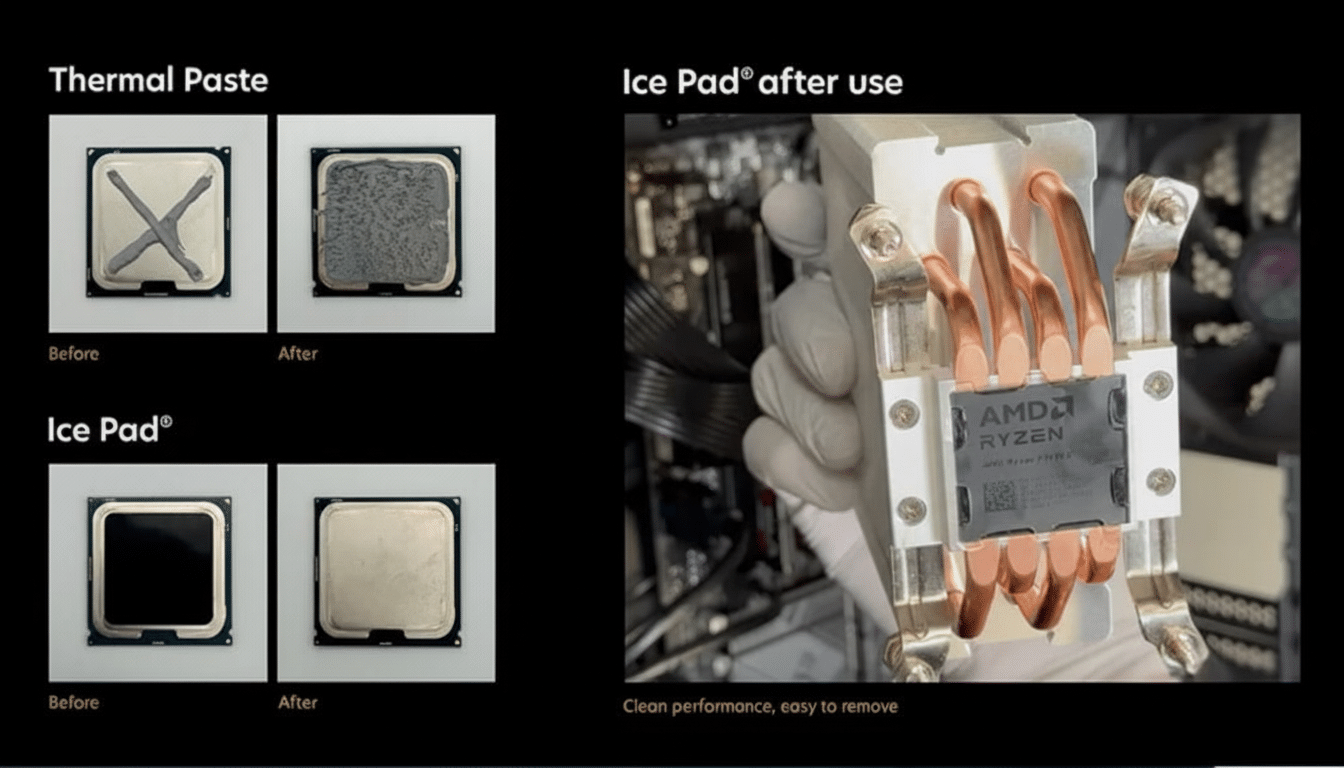

Unlike paste, which requires careful—and sometimes inconsistent—application, it reduces assembly time with a uniform pad. That applies to both DIY and prebuilt systems. Carbice has already signed a deal with CyberPowerPC to include the pad in some of the builder’s premium systems, suggesting that volume manufacturing and process control are part of what makes this product line sing.

How CNT pads differ from thermal pastes in real use

CPU heat dissipates along the interface into the cooler, thus through-plane thermal resistance is typically the most important measure. Carbice focuses on in-plane conduction because spreading heat side-to-side before it ever makes it into the heatsink can help minimize localized hot spots—a trait that’s especially useful with chiplet CPUs that have varying heat density across the package. The aluminum layer is an integrated heat spreader that complements the nanotube matrix.

For context, decent pastes like Noctua NT-H2 or Thermal Grizzly Kryonaut have conductivities of ~8–12 W/mK, and liquid metal compounds (like Conductonaut) are specified around 70 W/mK. Pads made of graphite are often specified in the range of 20–35 W/mK in-plane, and far less through thickness. The nuance: published conductivities by themselves don’t correlate directly to real-world CPU temperatures, since contact pressure, micro-roughness, and thermal interface thickness are dominant factors. Independent testing often uses standard methods, like the ASTM D5470 fixture, to determine total—not “raw”—thermal resistance.

Longevity claims and why they could matter for PCs

Carbice’s biggest claim is longevity: a pad that doesn’t dry out, pump-out, or need reapplication. That tackles long-standing pain points. With repeated thermal cycling, many pastes tend to move away from the hot spot or lose volatiles, presenting gradually increased thermal resistance. Research shared at IEEE electronics packaging conferences has shown paste performance can be rapidly reduced after prolonged cycling, a key reason data center operators and OEMs vigilantly track maintenance intervals.

The company also says we should expect the pad to get better with use as the interface “beds in,” which is possible if the nanotube network deforms slightly under heat and pressure, increasing true contact area. Whether that advantage extends across varying cooler mounting pressures and lapping is not something third-party labs are likely to be keen on testing.

Key performance questions the community will ask first

Fans will be searching for two types of information. First, solid apples-to-apples thermal comparisons against other pastes or graphite pads on the same CPU and cooler with controlled mounting tension. Second, reliability tests: thermal resistance drift after hundreds of power cycles and stability under vibration and over time. Some thermal specs from JEDEC and measurement protocols like ASTM D5470 would certainly lend credibility, but realistic PC tests—a sustained Cinebench or Blender load combined with a fixed-fan noise profile—will tell buyers what they need to know.

If the Ice Pad consistently shaves even a few degrees Celsius off mainstream pads, remains relatively unaffected by age, and aids ease of application, then maybe it should be found inside high-volume prebuilts. In a mature TIM market where there are lots of options clustered closely, reliability and repeatability can sometimes trump minor peak-performance deltas.

Electrical safety considerations and installation guidance

One issue circulating in the community, including on threads on TechPowerUp, is conductivity. Carbon nanotubes and aluminum are electrically conductive; this means misalignment over surrounding components might be dangerous. But unlike liquid metal, a solid-state pad won’t creep and is less likely to squeeze out under screw torque. On desktop CPUs with an integrated heat spreader and a suitable retention frame, the risk can be acceptable if size and placement are done properly. OEM validation continues to be necessary for open-die or tightly packed laptop boards.

Why OEMs will adopt CNT pads first for consistent builds

Speed and yield are of utmost importance on the factory line. A drop-in pad eliminates the potential for variation from pick-and-place, dispensed amount of paste, or setup. A CNT pad that maintains its thermal performance through temperature excursions and vibration during shipping can bring down return rates and reduce service expense. The CyberPowerPC partnership suggests those advantages: a guaranteed thermal baseline across several thousand units beats chasing a theoretical peak across only a small handful of enthusiast builds.

Bottom line and what PC builders and buyers should watch

Carbon nanotubes are a plausible route to improved heat interfaces, and Carbice’s Ice Pad is a thoughtful mix of materials science and practical construction. The headline numbers are promising, but the proof will be in third-party testing results that report total interface resistance, temperature deltas under real workloads, and long-term stability.

Once those boxes get ticked, look for additional prebuilts to switch from paste to pads, and another round of the race with premium TIMs from known brands like Thermal Grizzly, Noctua, and Fujipoly. To builders and buyers, the appeal is straightforward: cleaner installs, steadier temps, one less reason to ever crack a case open.