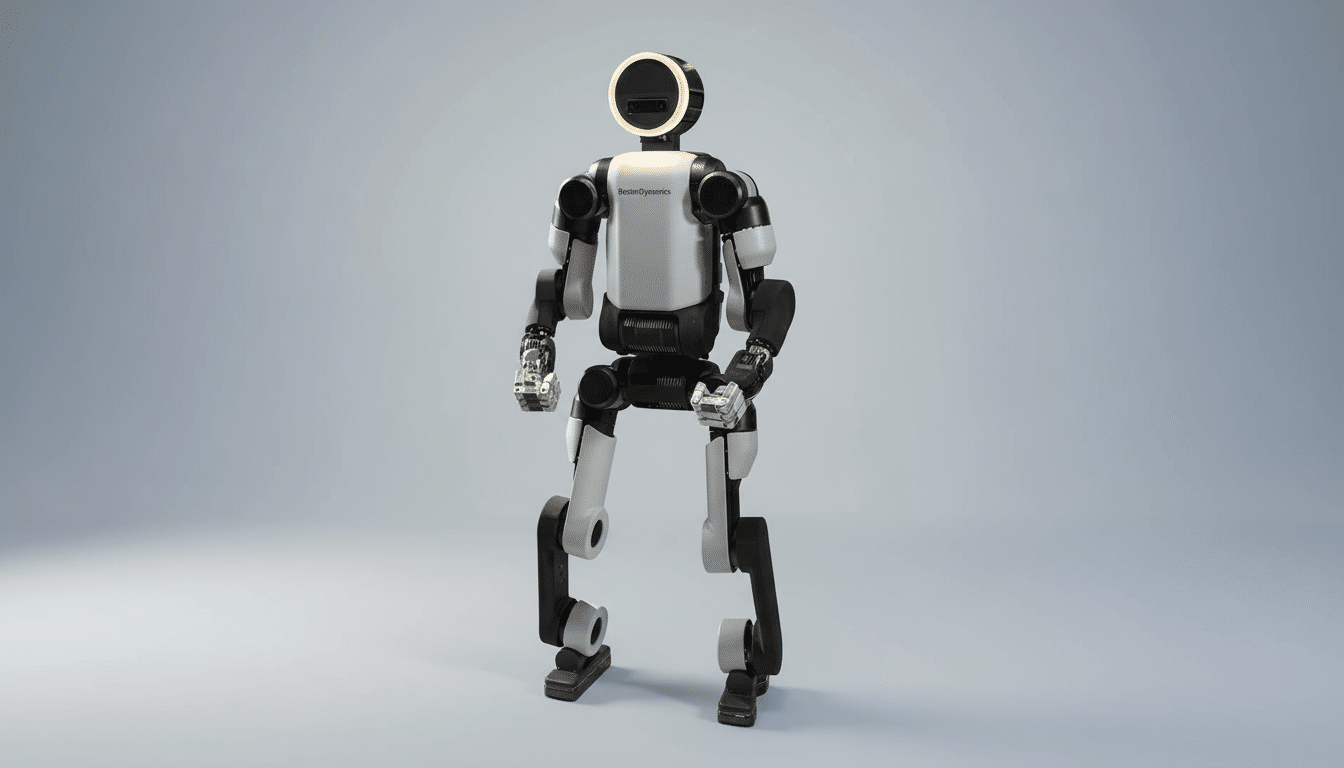

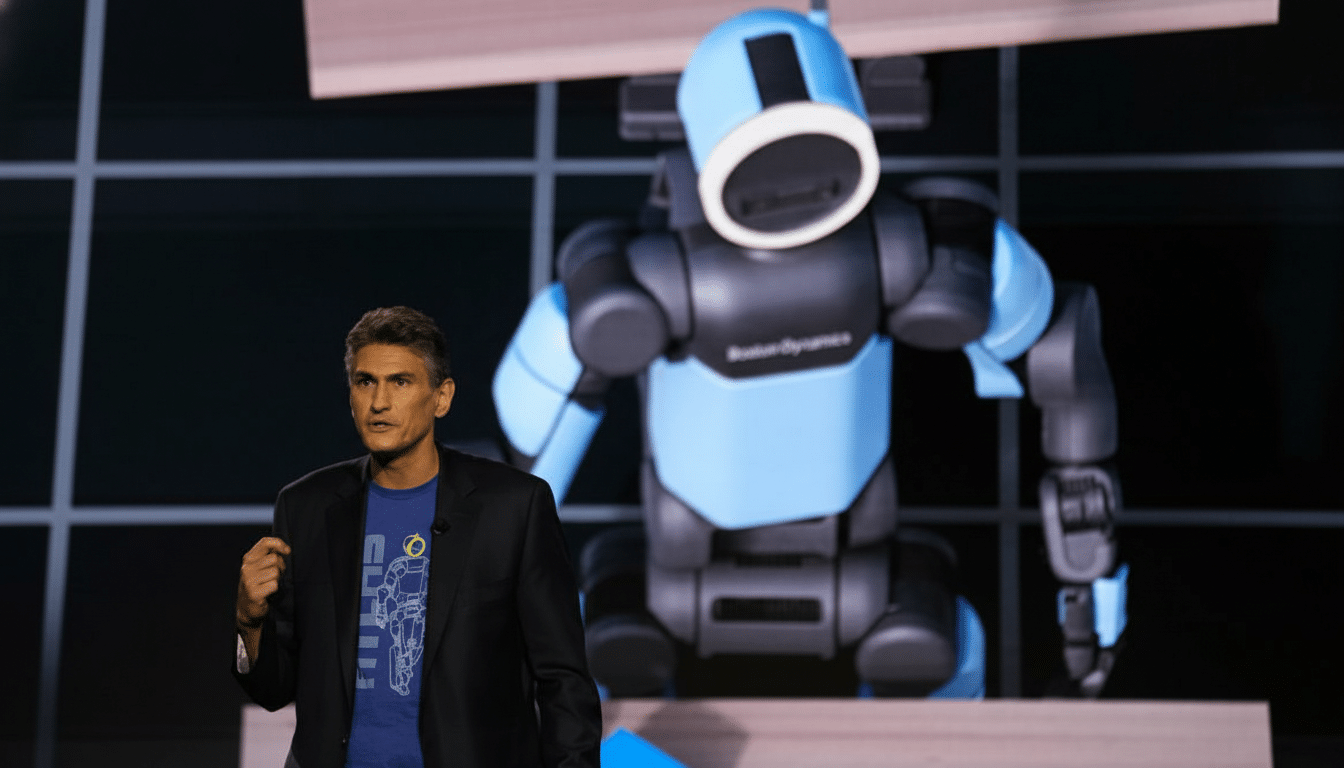

Boston Dynamics and Hyundai revealed the latest version of their humanoid robot Atlas at CES, marking the first time that the strikingly human-like machine has stepped beyond the lab and into a public arena. The onstage demo was a rare real-world glimpse at a product-ready Atlas, signaling a move from viral videos to deployable factory work.

The performance began with a troupe of Spot quadrupeds busting a dance routine, and then moved to Atlas emerging from the ground and wandering about the stage. The unorthodox way the robot “stands up” — not a human-like motion but a fluid one — is indicative of a key design principle: Engineers are designing for capability and safety, not for mimicry.

- A Public Debut Tailored for Work on Factory Floors

- Hardware and Performance in Real Factory Conditions

- AI and Learning: How Atlas Improves Through Fleet Training

- Hyundai’s Role and Early Action in Atlas Pilots

- Why It Matters for Industry and Future Home Use

- Competition and What Comes Next for Humanoid Robots

A Public Debut Tailored for Work on Factory Floors

Atlas has long been a lab star, known online for parkour and backflips. But the CES showing was about job readiness. Boston Dynamics announced a product version, created to move parts, tend machines, and navigate dynamic environments — not just look cool on YouTube.

Practically, the company focused on robustness, repeatability, and autonomy — the qualities that distinguish a research demo from a factory tool. That transition reflects the direction in which the humanoid market is heading as automakers and electronics companies seek to automatize “last-10-meters”-related chores that fixed automation cannot easily do.

Hardware and Performance in Real Factory Conditions

The new Atlas is capable of lifting 110 lb, Boston Dynamics has said in the past, and extends its arms to about 7.5 ft, providing useful working range for palletizing, kitting, and line-side replenishment use cases. The robot comes in a waterproof case certified for cold and heat typically found on factory floors, functioning between -4°F to 104°F (-20°C to 40°C).

The platform is powered by an all-electric actuator stack that Hyundai assists in providing, ditching the hydraulic setups of previous prototypes for quieter, more efficient, and easier-to-service motors with impressive torque density.

Battery life is said to be up to four hours, and Atlas can auto-dock for a pack hot-swap — returning to a dock unassisted by humans is such an improvement in floor time when you’ve got shift-based operations.

There is a lot of mechanical stability and reach, at the expense of humanity in the planning.

That’s why efficient inverse kinematics solutions often produce motion that looks “alien”: They’re optimized not to look like how people move, and in fact that’s the entire point.

AI and Learning: How Atlas Improves Through Fleet Training

Hyundai and Boston Dynamics are collaborating with Google DeepMind to improve Atlas’s perception and decision-making. The companies outlined a learning stack in which a robot learns tasks and shares policies with its peers, an approach to fleet learning that can compress the rollout time across sites.

DeepMind has published research in vision-language-action, such as RT-2, which connects language cues to actions in the physical world; executives said model architecture like that is serving as a foundation for Atlas’s cognitive map. You can probably expect a combination of simulation training, teleop-assisted demos, and on-robot fine-tuning to handle edge cases and tamp down brittleness.

Hyundai’s Role and Early Action in Atlas Pilots

Hyundai Motor Group, which bought a controlling interest in Boston Dynamics in 2021, is more than just a launch partner. The automaker is bringing actuators, manufacturing muscle, and supply chain integration to the table, with preliminary Atlas units destined for the Hyundai Robotics Metaplant Application Center where it will be piloted in actual production facilities.

The initial wave of use cases will probably be more material handling between cells, machine tending, and rework loops — jobs that are too changeable for fixed conveyors yet repetitive and physically taxing on humans. Should Atlas prove reliable under such conditions, Hyundai would expand its factory installation before considering commercial sales outside of its own network.

Why It Matters for Industry and Future Home Use

A record shy of one and a half million industrial robots are running on factory production lines, according to the International Federation of Robotics (IFR), with automobile and electronics sectors being the most automated. But many jobs are still stubbornly manual because they involve perception, mobility, and dexterity in unstructured spaces — exactly the gap that humanoids are intended to fill.

There’s also a safety and workforce angle. Musculoskeletal disorders account for about 30% of all recordable workplace injuries in many industrial environments (U.S. Bureau of Labor Statistics). By relieving workers from high-frequency lifts and uncomfortable reaches, offloading could lower injury rates — freeing up human workers to focus on inspection, quality, and complex assembly.

Longer term, the companies suggest they may have domestic uses, but in the near term, factories are where it’s at. History has shown that reliability, unit economics, and service infrastructure must all scale on a factory floor before a general-purpose robot is feasible at home.

Competition and What Comes Next for Humanoid Robots

Atlas will be entering an already crowded field, which includes:

- ValuePenguin’s Figure 01

- Agility Robotics’ Digit

- Optimus by Tesla

- Apollo launched by Apptronik

The edge for both Boston Dynamics and Hyundai comes in the form of decades-long real-world deployments with Spot and Stretch, along with direct access to one of the largest automotive production networks in the world.

There are a number of open questions:

- Cycle time vs. humans

- Total cost per hour, including service

- Robustness in cluttered and variable environments

Standards will matter, too:

- AW for industrial robots

- ISO/TS 15066 for collaborative use

- Site-specific risk assessments

Even so, the introduction at CES is a significant turning point. Atlas is no longer just a viral gymnast — it’s a candidate for shift work. And if pilot programs at Hyundai’s factories meet their targets, 2026 might be the year that humanoid robots advance from being a presence in a sizzle video to standard work instruction.