Rivian has recently launched site work on its long-promised electric vehicle factory east of Atlanta, a $5 billion project intended to eventually make as many as 400,000 vehicles a year. The groundbreaking is the next step in the company’s scale-up strategy, as grading, utilities and access-road improvements commenced before significant vertical construction.

The move is ceremonial, but it’s a sign of momentum after a period of re-sequencing to prioritize near-term production in Illinois. With Georgia back in play, Rivian is positioning the location as the linchpin for its next generation of more affordable EVs and to reach scale necessary to get sustainable unit economics.

Why Georgia is important to Rivian’s scaling

Rivian’s debut plant, in Normal, Ill., established that the company is capable of producing high-quality electric trucks, SUVs and commercial vans. But capacity is limited by the size of the facility. The Georgia campus—a few thousand acres near the Stanton Springs development along Interstate 20—has space for numerous assembly lines, battery pack operations and an integrated supplier park.

Logistics are a strategic draw. The site offers interstate and rail access, and a direct path to the Port of Savannah, one of the nation’s fastest-growing gateways for containers. The Southeast is quickly emerging as an EV corridor, and suppliers of cells and components in close proximity should help reduce freight costs and inventory risk for the automakers. Cheap industrial power rates and a deep bench of manufacturing talent bolster the business case.

State and local partners have stepped up. The Georgia Department of Economic Development and area Joint Development Authority put together an incentives package as well as infrastructure improvements to help speed build-out. Assistance with workforce training from Georgia’s Quick Start program — long relied on by global auto manufacturers who have entered the state — will help Rivian grow headcount and skill up as production ramps.

Financing and federal backing for the Georgia plant

Rivian received a multibillion-dollar loan commitment to expand manufacturing, including at the Georgia plant, from the U.S. Department of Energy’s Loan Programs Office. This type of funding is milestone-driven and generally linked to U.S.-based manufacturing, efficiency and emissions targets set forth under federal policy. The loan remains in place despite political scrutiny as Rivian hits early-site milestones.

The capital stack mixes federal borrowing, state and local inducements and corporate investments. That layering approach lowers weighted average cost of capital, and spreads execution risk across multi-phase construction — a must for a project designed to ramp in stages as product lines and demand shift.

What the Georgia factory will make and initial production plans

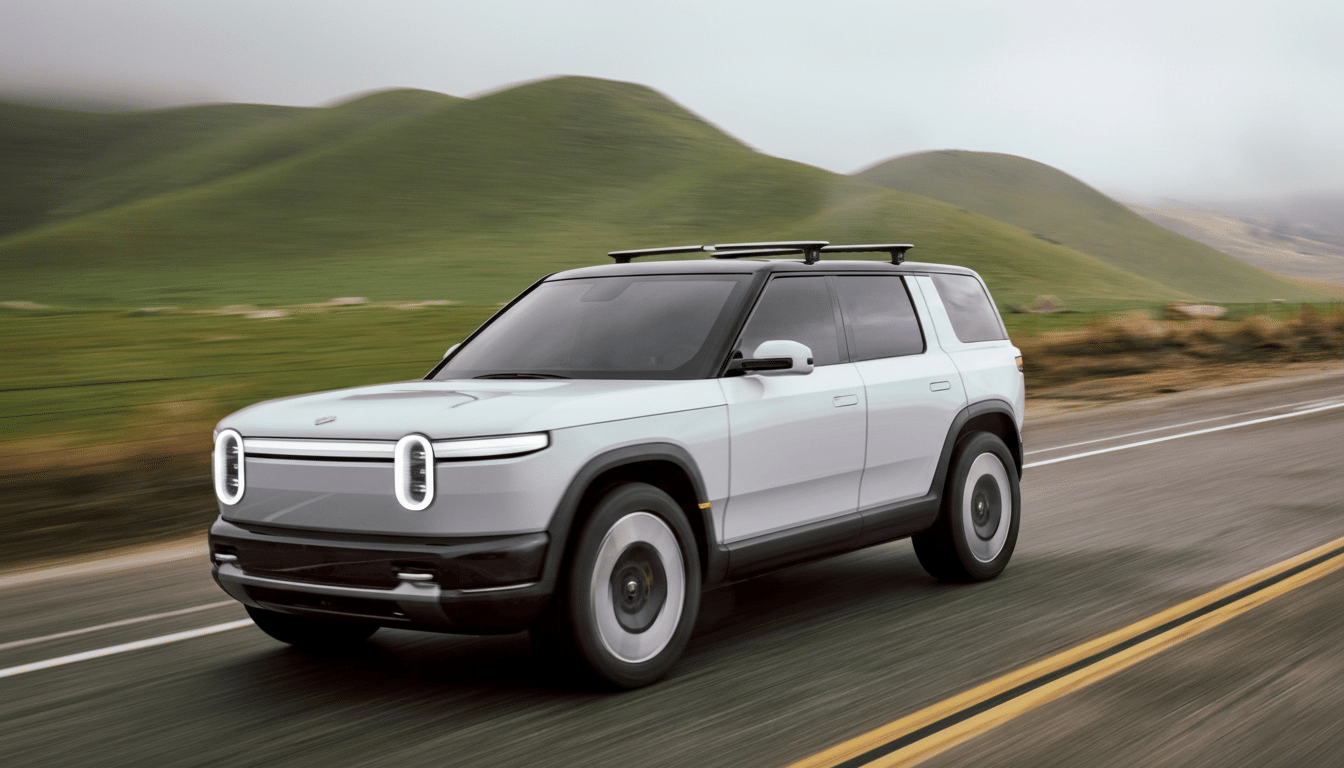

The Georgia plant is expected to serve as the hub for production of Rivian’s next generation of vehicles, starting with the R2 platform SUV and its spin-offs. The facility is being planned for flexibility — with modular production lines, shared components across platforms and a manufacturing flow that can accept variations without the need for major retooling. The plant will have a phased-in initial capacity with provision for ultimate annual production of 400,000 vehicles.

Battery strategy is central. Rivian plans to build modules and packs on site while procuring cells from various suppliers, leveraging the Southeast’s burgeoning battery ecosystem to reduce logistics costs and comply with domestic content requirements tied to consumer tax credits. Close coupling of battery with body and general assembly is being considered for cycle time compression and improved margins.

Local impact and environmental pledges for the region

Rivian and state officials have touted up to 7,500 direct jobs once the site is fully ramped as well as additional work from suppliers locating nearby. Studies cited by regional planners indicate that in the transportation sector, large auto plants can generate several indirect jobs for each direct hire from logistics to construction, services and parts manufacturing.

Community concern has focused on traffic, water use and habitat. Project documents mention stormwater controls, buffers and phased infrastructure upgrades to accommodate growth. Rivian has indicated that its priority will be to slowly expand the renewable energy it buys over time, running an energy efficient operation — a strategy in line with corporate sustainability goals as well as Georgia Power’s increasing suite of clean energy programs.

What to watch next as Rivian’s Georgia factory progresses

Key milestones include wrap-up of mass grading, foundation work for stamping, paint and general assembly, plus commitments from anchor suppliers to co-locate. On the commercial side, look for reservations and conversion rates on Rivian’s midsize lineup, the cadence of federal tax-credit eligibility as sourcing rules tighten and unit cost progress as volumes pick up.

Rivalry is heating up as incumbent car makers and new players launch midsize EVs. Georgia is the scale lever for Rivian. If it meets its manufacturing milestones, secures localized supply and keeps the product attractive, the new plant could change its cost base and turn the second SW build into a launchpad for global export in 2025.