A group of hardware modders has turned the integrated heat spreader of AMD’s Threadripper Pro 9995WX into a fully functional waterblock—and the thermal performance is jaw-dropping. In tests shared by mod channel Geekerwan and highlighted by enthusiast outlets, the 96-core workstation chip sustained an all-core overclock beyond 5.3GHz while peaking around 50–52°C, even as CPU power crested 1,340W and total system draw approached 1,700W. For a part nominally rated at 350W TDP, that’s a dramatic proof of what targeted, high-flow liquid cooling can do when you move heat extraction right to the source.

How They Turned the IHS Into a Water-Cooling Block

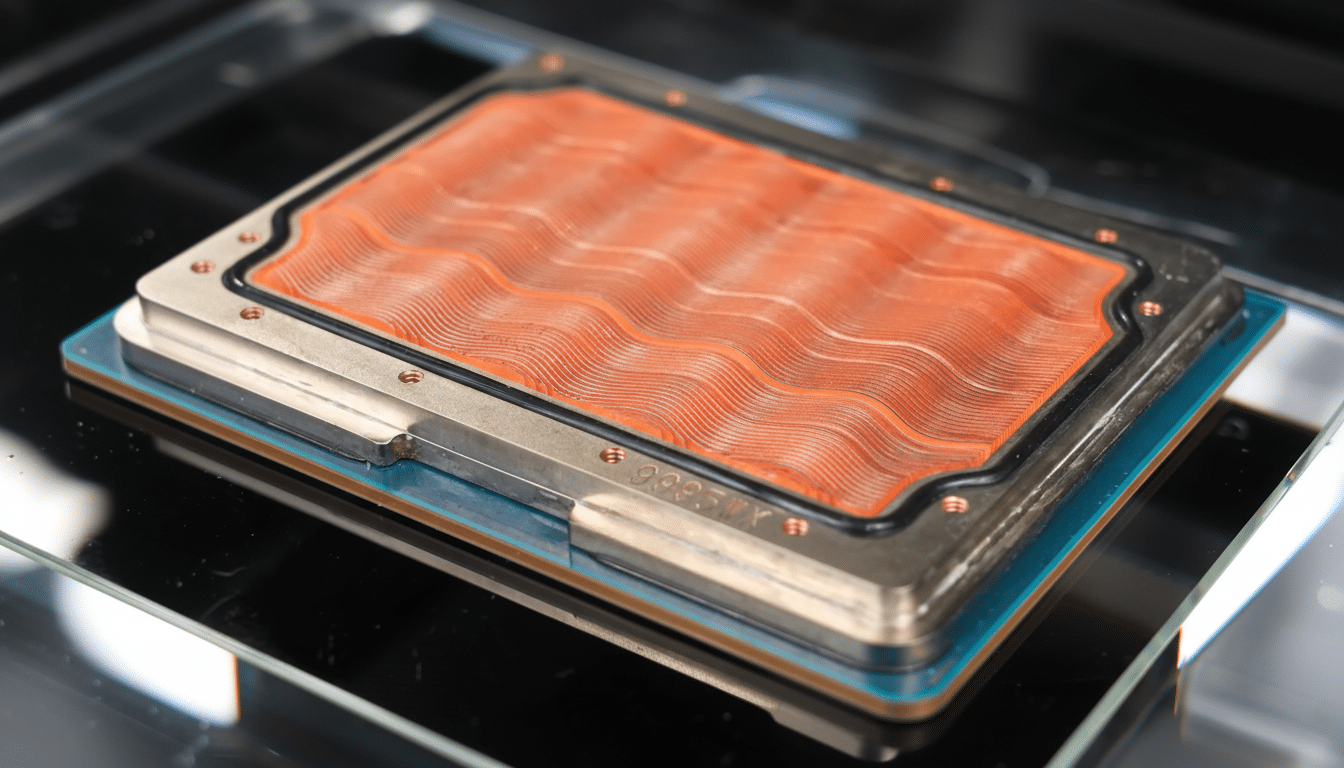

Instead of bolting a conventional cold plate on top, the team machined microchannels directly into the CPU’s nickel-plated copper IHS, then designed dual inlet and dual outlet paths to push coolant straight over the hottest zones. The layout was mapped to the chiplet arrangement under the lid so that fresh coolant first strikes the densest thermal hotspots before exiting through the sides. The approach borrows from microfluidic concepts championed in recent data center research, including work Microsoft Research has presented on channeling liquid closer to silicon to slash thermal resistance.

By converting the IHS into a flow body, the mod eliminates several layers of interface typically stacked between die and coolant—TIM, IHS-to-cold-plate contact, and internal block impedance—shrinking the distance heat must travel and improving heat flux distribution across the fluid. That tighter thermal coupling is why the setup could tame sustained, kilowatt-class loads that would overwhelm standard AIOs or even high-end custom loops.

A Cooling Stack Built for Sustained Kilowatt Loads

Feeding the modified IHS was a large external loop: a roughly 140L reservoir, an industrial chiller rated around 800W of cooling capacity, and a pair of robust 50W Bosch automotive pumps (sourced from a Mercedes application) to maintain flow through the long run and dense channels. With ample thermal mass and aggressive circulation, inlet temperatures stayed sub-ambient, further widening the headroom window. While this may sound exotic for a desktop, the design echoes techniques long used in HPC labs where high-flow cold plates and chillers are standard fare for dense packages.

Importantly, the team targeted coolant impact where it matters most. Chiplet CPUs concentrate heat in multiple small regions rather than a single monolithic die, so the parallelized, on-IHS channel network helps avoid the “central hotspot” problem many traditional blocks struggle with on large, multi-die packages.

Numbers That Reframe What’s Possible in CPU Cooling

With clocks locked at roughly 5.325GHz across all 96 cores, the chip posted standout results: about 205,000 points in Cinebench R23, 10,080 points in Cinebench 2024, and 41,478 in the early Cinebench 2026 build, according to Geekerwan’s testing. Those figures put the run squarely in record-chasing territory for a workstation-class CPU. More striking than the scores, though, were the thermals: at greater than 1.3kW CPU package power, the peak temperature hovered near the low-50s Celsius, a range many stock coolers struggle to maintain at a third of the load.

As enthusiasts noted, this comes at a steep price. The Threadripper Pro 9995WX alone is a five-figure component in many regions, and precision machining an IHS, sealing it, and pairing it with an industrial chiller is not a weekend-budget project. Still, the demonstration underscores how much performance modern chiplets leave on the table when constrained by conventional heat removal.

Why This Mod Matters for the Future of Cooling

Workstation and data center CPUs keep pushing power density up as core counts and clocks scale. Traditional cold plates—optimized for older, monolithic dies—often fail to align flow with today’s hotspot map. Direct-to-IHS or even direct-to-die microchannel cooling could become a bridge technology before full-blown in-package liquid cooling or vapor-integrated lids reach the mainstream. Research groups and industry players are already exploring similar ideas; this mod simply shows what happens when you execute them with care on a retail chip.

The commercial takeaway is hard to ignore: there’s a clear niche for purpose-built, chiplet-aware waterblocks that either replace the IHS or bond to it with minimal thermal penalty. For boutique workstation builders and extreme overclockers, shaving a few °C under heavy load often translates to measurably higher sustained clocks and better stability headroom.

Caveats, Costs, and What Comes Next for This Mod

This level of modification carries risk. Precision milling alters the structural role of the IHS, and sealing, plating integrity, and coolant chemistry must be managed to avoid leaks, corrosion, or galvanic reactions over time. It also depends on a chiller-backed loop—well beyond the pump-and-radiator kits common in PCs.

Even so, the experiment pushes the conversation forward. If manufacturers embrace replaceable lids or offer IHS variants with integrated channels and standardized fittings, we could see safer, warranty-friendly versions of this concept. Until then, efforts like Geekerwan’s—corroborated by third-party coverage and community scrutiny—provide a compelling data point: when coolant meets the hotspots directly, multi-kilowatt-class silicon can run fast, stable, and astonishingly cool.