Amazon has quietly shelved Blue Jay, a multi‑arm warehouse robot prototype introduced last fall as an “extra set of hands” for same‑day delivery sites. The company is winding down the pilot after a short run, reallocating the underlying technology and most team members to other automation programs, according to reporting from Business Insider, later corroborated by TechCrunch.

It’s a rare public retreat in Amazon’s otherwise relentless robotics march, but one that underscores how often ambitious warehouse concepts are tested, timed, and—if they miss operational or safety targets—sunset quickly.

What Blue Jay Was Built To Do In Same‑Day Fulfillment

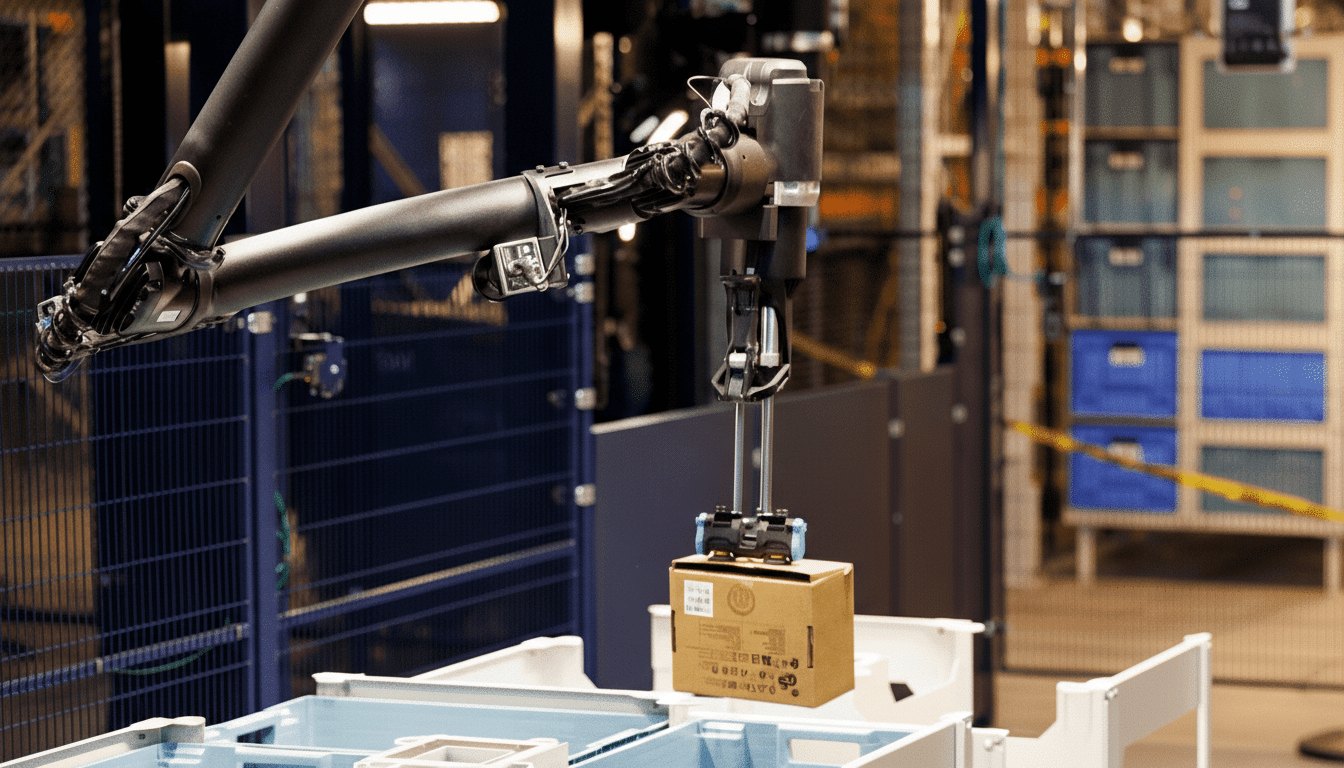

Blue Jay was designed as a multi‑arm helper station for fast‑cycle facilities, where orders move from click to doorstep in hours. In early demos, the system coordinated robotic limbs to handle awkward or varied packages, complementing associates at packing or staging points where throughput and ergonomics are most strained. Initial testing took place at a same‑day site in South Carolina.

Amazon now characterizes Blue Jay as a deliberate prototype—useful for learning, never guaranteed to scale. A spokesperson told TechCrunch the company is accelerating deployment of Blue Jay’s core components across other systems, rather than commercializing the stand‑alone configuration itself.

Why The Project Was Grounded Under Amazon’s Workflow Realities

Shutting down a pilot seldom signals failure of the underlying tech; it often reflects misfit with today’s workflow economics. In high‑mix fulfillment, robots must clear three gates: safety, reliability, and cycle time. Multi‑arm cells can excel at dexterity but struggle to beat simpler, modular stations on picks per hour when you factor in guarding, human‑robot collaboration limits, and reset times after exceptions.

Safety certification also shapes pace. Collaborative systems that operate near people are typically constrained by standards such as ISO/TS 15066, which cap speeds and forces unless additional sensing or separation is added. The result can be a performance tax that turns a promising lab capability into a floor‑level bottleneck.

Then there’s the return on capital. Amazon has tightened fulfillment spending while reorganizing its network around regional same‑day hubs. In that environment, technologies with immediate, network‑wide leverage—think autonomous mobile robots moving carts or software that boosts sortation yield—tend to outrank bespoke multi‑arm cells that improve a thin slice of the line.

Where The Tech Goes Next Inside Amazon’s Robotics

The company says the perception, motion planning, and force‑control advances from Blue Jay will be folded into other platforms. That could mean better grasping for item‑handling arms like Sparrow, heavier‑duty sorting for Cardinal, or smarter end‑effectors rolled into existing pack and sort stations. Amazon has made similar handoffs before—pilots that don’t scale still seed breakthroughs in vision models, gripping geometry, and exception handling that boost mature systems.

Amazon already fields one of the world’s largest robot fleets—more than 750,000 mobile and stationary units by the company’s recent counts—born from its 2012 Kiva acquisition and expanded through homegrown platforms such as Proteus (autonomous floor robots), Sequoia (a high‑density storage and induction system Amazon says can speed inventory processing by as much as 75% and cut order cycle times up to 25%), and a pilot with Agility Robotics’ Digit for tote handling.

A Pattern In Amazon’s Evolving Robotics Strategy

Amazon’s playbook favors parallel bets, aggressive A/B testing on live lines, and rapid redeployment of talent and IP when a concept tops out. Business Insider’s and TechCrunch’s accounts of Blue Jay fit that pattern: short cycles, clear kill criteria, and quick absorption of what worked. That approach helps the company push the frontier on piece‑picking and human‑robot collaboration without locking into expensive dead ends.

There’s also a safety dimension. Amazon says its automation aims to reduce repetitive strain and awkward lifts, a common source of musculoskeletal injuries in fulfillment. Labor advocates, including the Strategic Organizing Center, have countered that injury rates at some Amazon facilities remain above broader industry averages. Whether Blue Jay directly addressed those risks or introduced new ones under tight cycle times would have been a central factor in any go‑to‑market decision.

What To Watch Next In Amazon’s Warehouse Automation

Blue Jay’s sunset is not a retreat from warehouse robots so much as a recalibration toward platforms that scale faster. Watch for upgrades to Sparrow’s grasp reliability on odd‑shaped items, expanded Proteus coverage across same‑day nodes, and whether Amazon moves beyond pilots with Digit in tote transfer and buffer zones. If Blue Jay’s perception stack shows up in those systems, the project will live on in the metrics that matter most: higher sustained throughput, fewer exceptions, and safer shifts for associates.