Upside Robotics says its autonomous field robots are helping corn growers use far less fertilizer while boosting timing precision and slashing waste. The Waterloo startup reports an average 70% reduction in nitrogen and nutrient inputs for its customers, translating to roughly $150 in savings per acre and sharply lower runoff risk—results that have kept every paying customer on board so far and drawn a waitlist of more than 200 farms.

How the Robots Time and Target Nutrients Precisely

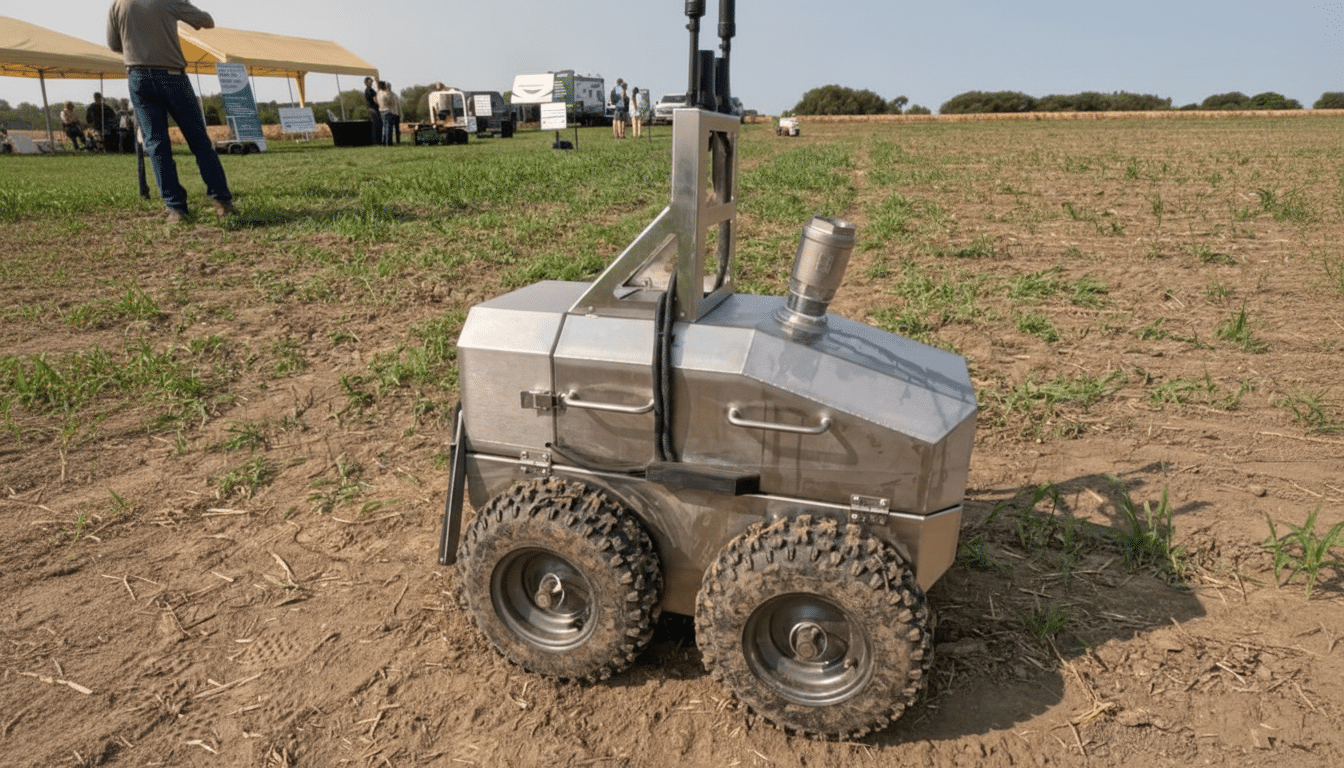

The company’s lightweight, solar-powered robots travel crop rows and micro-dose nutrients exactly when plants can use them. Proprietary software ingests weather patterns, soil characteristics, and crop growth signals to determine dose and timing, then executes in-season applications at plant or zone level. The autonomy is paired with a gentle footprint: smaller machines reduce soil compaction compared with traditional high-clearance applicators, which matters for root health and water infiltration.

- How the Robots Time and Target Nutrients Precisely

- The Agronomy Problem Upside Targets in Corn Systems

- Early Results and Farmer ROI from In-Season Nutrition

- Why It Matters for Climate and Water Quality Outcomes

- Scaling Strategy and Funding to Expand Service Footprint

- The Adoption Curve on the Farm for Autonomous Nutrition

- What to Watch Next for Performance, Uptime, and Impact

Upside’s team built and iterated hardware in the field with growers, moving from manual remote-control trials to fully autonomous systems in a compressed timeline. That close-up learning paid off in practical features—row-following in tall corn, redundancy for wet conditions, and battery-solar hybrids—to keep the robots working when nutrients are needed, not just when a spray rig is available.

The Agronomy Problem Upside Targets in Corn Systems

Conventional fertilizer programs often front-load nitrogen before planting or early in the season. Research from Midwestern land-grant universities shows corn’s peak nitrogen demand arrives later, around rapid vegetative growth through tasseling. When fertilizer is applied too early—or in a single heavy pass—only a fraction is taken up; the rest is vulnerable to leaching and denitrification, particularly after storms.

Global estimates from the Food and Agriculture Organization put nitrogen use efficiency for cereals in the 30–50% range. That aligns with farmer experience: much of the fertilizer they pay for never reaches the plant. The USDA’s Economic Research Service has also noted that corn accounts for roughly 40% of U.S. nitrogen fertilizer use, underscoring the scale of the opportunity if timing and placement improve.

Early Results and Farmer ROI from In-Season Nutrition

Upside Robotics started on a handful of fields, then expanded rapidly after demonstrating that well-timed in-season applications could meet crop needs with less product. Customers report cutting total fertilizer by about 70% with no yield penalty, according to the company, which syncs with university findings that split or variable-rate applications can trim nitrogen by 10–30% under many conditions. The robots extend that logic by executing more, smaller passes—without adding labor or equipment hours.

The economics are straightforward. After a period of volatile fertilizer prices, many operations still budget heavily for nitrogen. Saving $150 per acre while preserving yield buffers growers against margin swings. Because the platform is service-based, farms also avoid big capital outlays and the maintenance burden typical of precision equipment.

Why It Matters for Climate and Water Quality Outcomes

Fertilizer efficiency is more than a cost line; it’s a climate and water issue. The Intergovernmental Panel on Climate Change identifies nitrous oxide—a byproduct of nitrogen fertilizer losses—as a potent greenhouse gas with a high warming impact over a century-scale horizon. At the watershed level, nitrogen and phosphorus runoff feed algal blooms and hypoxia, problems visible from the Great Lakes to the Gulf of Mexico. By dosing nutrients closer to uptake, Upside’s approach aims to reduce the nitrogen left in soils after rainfall events, when it’s most likely to escape.

The robots’ solar assist also trims the operational emissions that come with heavy field equipment. While those reductions are smaller than the avoided nitrous oxide, they help farms meet emerging sustainability metrics demanded by grain buyers and lenders.

Scaling Strategy and Funding to Expand Service Footprint

The company moved from pilot plots to serving over a thousand acres in its second season and plans to more than double coverage next. It reports 100% customer retention, driven by consistent savings and ease of integrating with existing fertility plans. Upside recently closed a $7.5 million seed round led by Plural with participation from Garage Capital and founders of Clearpath Robotics—experienced backers in autonomy and industrial robotics. The capital is earmarked for more robots, better sensing, and expansion beyond Canada with an eye on the U.S. Corn Belt.

The Adoption Curve on the Farm for Autonomous Nutrition

Farmers have long been told to “apply the right product at the right rate, right time, and right place.” The 4R Nutrient Stewardship framework is sound, but hitting all four R’s at scale is tough with large, labor-limited operations. Upside’s pitch is that autonomy and fine-grained software finally make that agronomic ideal practical—and profitable—without requiring growers to overhaul their entire program on day one.

That message appears to resonate. A growing waitlist suggests willingness to adopt when the return is clear and the service is simple. If performance holds across different soil types and weather regimes, the model could complement other precision tools like variable-rate prescriptions and enhanced-efficiency fertilizers rather than replace them.

What to Watch Next for Performance, Uptime, and Impact

Key proof points this season will include yield stability in wetter springs, robot uptime during peak growth windows, and measurable reductions in residual soil nitrate after harvest. Independent validation—from universities, grower groups, or conservation organizations—will matter as the company enters more competitive markets. If Upside keeps delivering 70% fertilizer cuts at scale, its small robots could have an outsized impact on the economics and environmental footprint of corn.