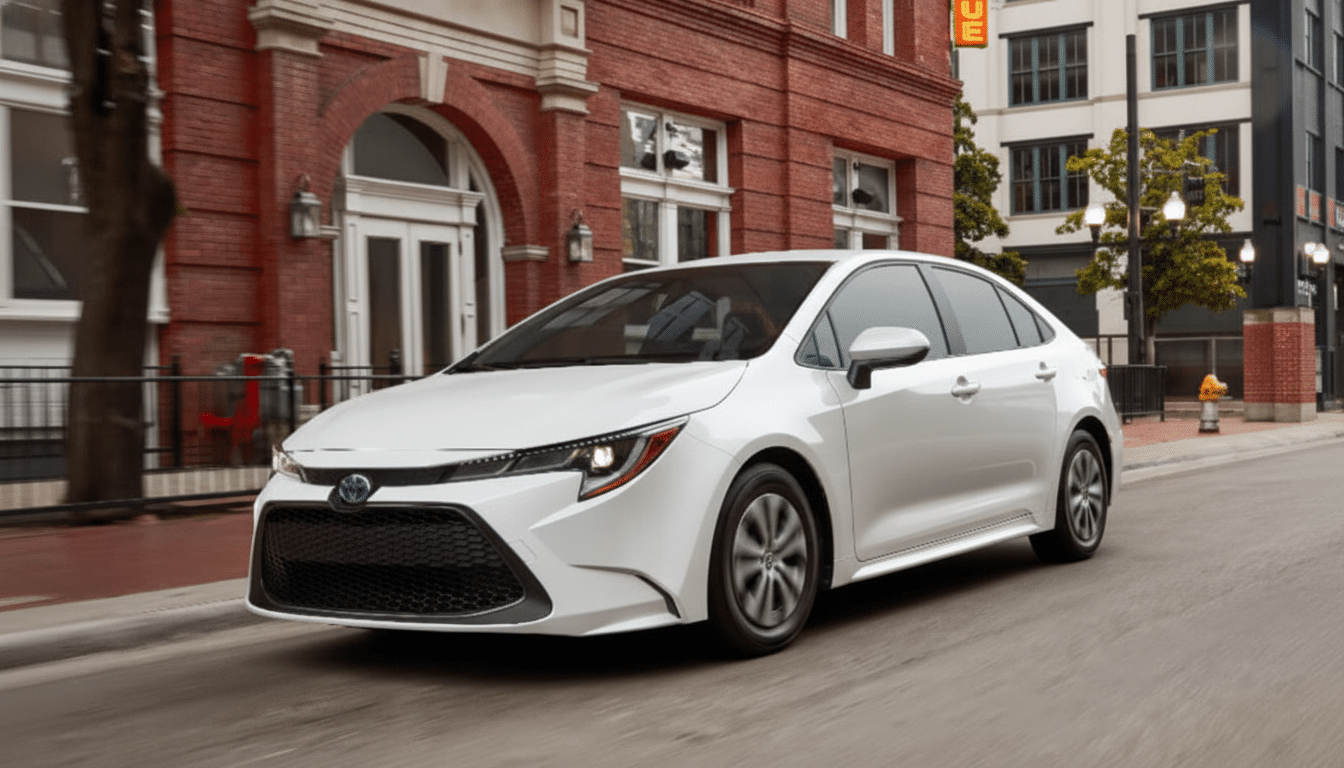

In a significant bet that will help bring environmentally friendly vehicles to the masses, Toyota’s investment plans in five factories across the United States amount to $912 million in part to increase output of hybrid-ready engines and critical electric drive components. The announcement, part of a larger initiative to spend as much as $10 billion on operations in the United States, includes the first Corolla Hybrid to be built in the United States and a major expansion at the company’s powertrain plant in Buffalo, West Virginia.

Why Hybrids Make Sense for the U.S. Market Today

Hybrids have taken the baton as America’s hybrid moving forward, quietly assuming the role of center of gravity in America’s journey to electrification. Market share for hybrids, according to data from S&P Global Mobility and Cox Automotive, has been climbing into the high single digits — near 10% in new-vehicle sales, surpassing BEV growth in a number of quarters. Toyota, which for years has been the leader in this segment, has ridden that wave: according to company filings, electrified vehicles have represented recently about 30% or close to 40% of the automaker’s U.S. volume, and they’ve done so with models like RAV4 Hybrid, Camry Hybrid, Prius and Sienna leading that stack.

- Why Hybrids Make Sense for the U.S. Market Today

- Inside Toyota’s $912 Million Investment in U.S. Plants

- Policy and the Supply Chain Calculus Shaping Hybrids

- Competitive Context and Risks in the Hybrid Market

- What It Means for Buyers and Sellers of Hybrids

- The Bottom Line on Toyota’s U.S. Hybrid Expansion Plan

For many buyers, the math is simple: Hybrids offer large efficiency gains without requiring home charging or relying on public infrastructure. According to EPA estimates, typical fuel economy is 30–40% better than equivalent gasoline-only cars, and cost (including purchase and installation) tends toward conventional vehicles rather than BEVs.

Inside Toyota’s $912 Million Investment in U.S. Plants

The biggest slice, or roughly $453 million, goes to Toyota’s Buffalo plant in West Virginia to increase the production capacity of 4-cylinder hybrid engines that are installed in a raft of products, and new-generation hybrid transaxles and electric motor stators that comprise vital elements used for engaging its recently developed systems. The shift of those parts to West Virginia should make for easier logistics and greater supply reliability for high-demand models.

About $125 million is allocated to kick-starting U.S. assembly of the Corolla Hybrid, including tooling and line changes at Toyota’s Mississippi plant. Extra money will help production capacity and component updates in Kentucky and Missouri to provide engine, transaxle and e-motor output for its predicted sales of hybrid sedans, crossovers and trucks.

Policy and the Supply Chain Calculus Shaping Hybrids

Toyota’s timing is amid the fast-shifting policy landscape. As part of Treasury guidance for the Inflation Reduction Act, tighter battery content and component rules have reduced eligibility for some BEV tax credits, increasing the incentive to build hybrids which need much smaller battery packs and fewer rule-affected minerals overall. Meanwhile, higher tariffs on Chinese EVs and some battery components boost the value of local production and robust supplier networks.

It is also consistent with EPA’s 2027–2032 regulatory emissions standards for light-duty applications that are technology-neutral and can be addressed by a menu of solutions.

The hybrids enable immediate fleet-wide emissions reductions without reliance on charging buildout, a position Toyota executives have steadfastly stood by and that is supported by industry groups like the Alliance for Automotive Innovation.

Competitive Context and Risks in the Hybrid Market

The market is also moving Toyota’s way. Ford has raised the levels of hybrid penetration in F‑150 and Maverick, over at Honda, CR‑V and Accord lineups now leaning heavily toward hybrids. General Motors has indicated a renewed interest in plug-in hybrids for certain categories. It is this 16th scale race that matters more than headline EV range, which is only tangentially related to electric powertrain cost, margins and economies of scale—areas where hybrids have got it made with smaller batteries and mature manufacturing.

Still, there are trade-offs. A fast BEV price decline, accelerated unrolling of charging under federal NEVI programs or game-changing battery chemistries could swing demand back toward full electrics. Toyota is hedging its bets with R&D in next-generation batteries and solid state cells, but in the short term it’s clear which track it’s prioritizing — building what it can make profitably at scale today.

What It Means for Buyers and Sellers of Hybrids

With more domestic component capacity, wait times should be shorter and trim availability will increase, while pricing for high-demand hybrids should stabilize. Look for broader hybrid availability in core nameplates and ongoing deployment of electrified powerplants across the trucks and SUVs where Toyota has already introduced its i‑FORCE MAX systems in Tundra and Tacoma. For shoppers, that translates to greater availability of vehicles bringing 35–40 mpg combined in segments where you normally find much less.

Dealers, meanwhile, receive a product mix that turns quickly, appeals to buyers who make purchase decisions based on payment and avoids the charging and trade-in complexities that have chilled some BEV transactions, according to recent surveys from Cox Automotive.

The Bottom Line on Toyota’s U.S. Hybrid Expansion Plan

Adding to that WALL-E echo, Toyota’s $912 million push is less a pivot than an acceleration of a thesis it has laid out for years: Incremental electrification at scale can deliver instant emissions cuts, solid customer value and strong factory utilization. As domestic hybrid content climbs and Corolla Hybrid production begins on U.S. soil, the automaker is centering its lineup exactly where American demand for hybrids happens to be growing the fastest—right in the sweet spot of hybrids.