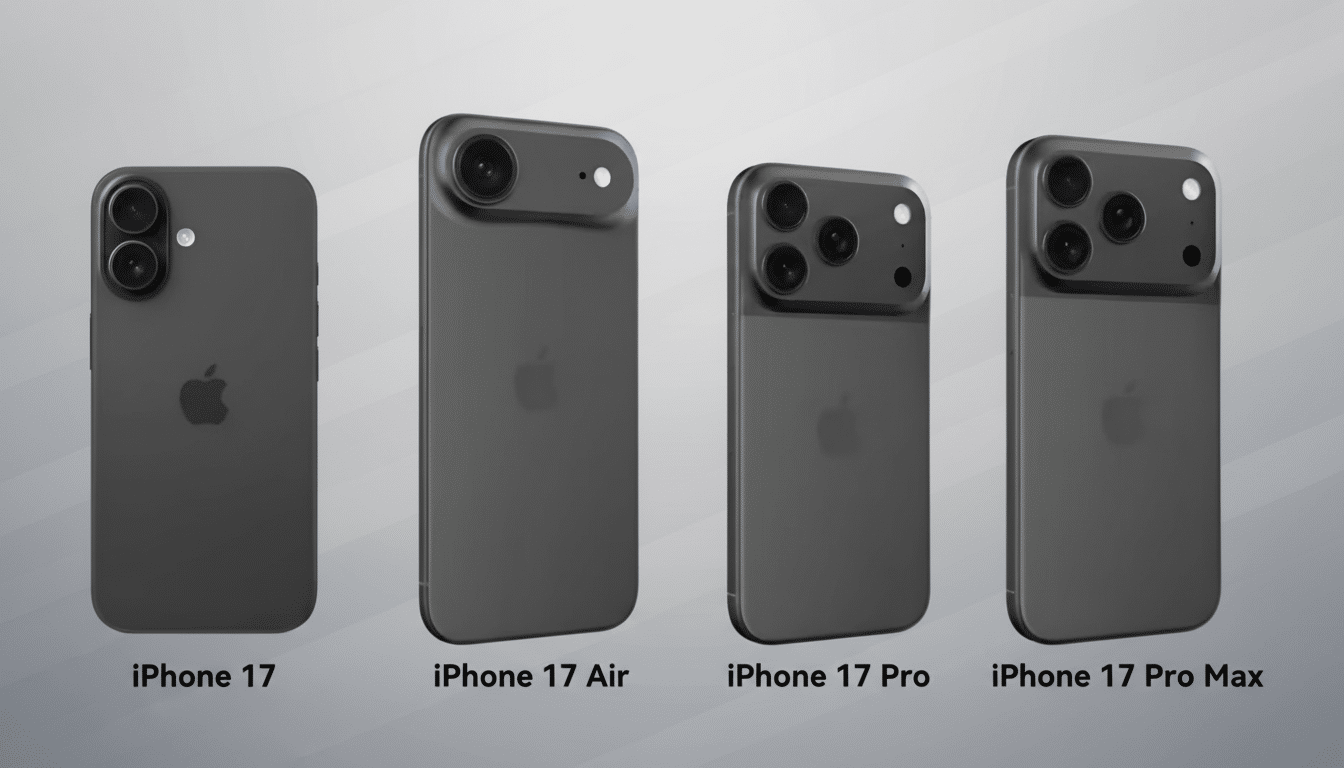

Scratchgate! That’s what users have decided to call how easily the iPhone 17 Pro and Pro Max have started picking up scuffs and chips on their colored frames. As in previous gadget mini-controversies, the name ricocheted across social platforms within hours of store demos and early units showing wear that seemed out of line with a flagship price tag.

What “Scratchgate” actually is on iPhone 17 Pro

The basic complaint/message is simple: the new Pro models feature an anodized aluminum enclosure whose tinted outer layer smudges easily.

- What “Scratchgate” actually is on iPhone 17 Pro

- Where iPhone 17 Pro frame scratches usually appear

- Anodizing explained: how colored aluminum behaves

- The chipping issue of the camera bump on Pro models

- Why Apple changed materials for the iPhone 17 Pro

- How to avoid visible wear on iPhone 17 Pro frames

- What Apple might switch up next to reduce scuffs

Even casual pockets-and-keys activity is leaving visible lines that show raw, silver aluminum around darker finishes like Deep Blue and the bright orange choice.

Shoppers quickly noticed scratches on in-store demo models, and journalists, including Bloomberg’s Mark Gurman, pointed out how the move away from last year’s titanium comes with trade-offs for durability. Although the phones generally function well, it’s difficult not to notice the cosmetic wear on colored frames.

Where iPhone 17 Pro frame scratches usually appear

Most marks are showing up around the edges, in the corners and around the camera island. Because the anodized dye lives on the surface, any scratch that penetrates through to this layer produces a high-contrast band — especially jarring on darker shades. Light shades can mask scuffs more effectively, but the principle is identical: once the topcoat is damaged, you see blazing aluminum.

Thus far, the reports revolve around the iPhone 17 Pro and Pro Max chassis. Display glass scratch resistance is the usual for today’s smartphones (wear regularly sets in around Mohs 6–7 on average), but this cycle, it’s the frame finish that’s flowing ink.

Anodizing explained: how colored aluminum behaves

Anodizing is like a refined, hardened-oxide “skin” that can be dyed any color on aluminum. It feels premium and helps keep the weight lower, but it does act like a coating with a limited thickness. Scratch through it, and the color comes out with it. Materials engineers commonly refer to this as a candy shell: once scratched, the core will show.

To prevent the thin colored layer from being pulled away in sharp corners, standards bodies like ISO (e.g., 7599 for anodic oxidation of aluminum) and U.S. military specs like MIL-A-8625 recommend generous radii on exposed edges. If design tolerances dictate sharp lines, the fired finish at those edges is more likely to chip or flake.

The chipping issue of the camera bump on Pro models

Durability testers, such as JerryRigEverything, are identifying the camera housing as a potential weak point this year. More acute corner geometries around the camera island focus stress in the anodized layer. That combination — thin dyed coating and hard corner! — is a recipe for small chips that don’t heal, but instead simply accumulate blemishes you can’t easily cover up.

That is not to say the frame is structurally inept. It’s just that the colored surface is a cosmetic finish and has predictable modes of failure when it encounters gritty abrasives, keys, zippers or even rough surfaces of tabletops.

Why Apple changed materials for the iPhone 17 Pro

Aluminum is lighter, more readily colored in a uniform manner and easier to machine than titanium. It also disperses heat effectively — handy for high performance maintained over time. The downside is cosmetic resilience. Titanium, which was featured on last year’s Pro line, won’t take color the same way and is generally finished in ways that differ from aluminum — methods that can hide small defects more easily at the cost of diminishing potential for variety.

How to avoid visible wear on iPhone 17 Pro frames

The common-sense solution is simple: slap a case or an edge-protecting bumper on the phone as soon as you open its box. A slim case will guard the anodized edges from scrapes and dull impacts, and a raised lip can help protect the corners of the camera island. Skins can also help by providing a sacrificial layer, although they will not cushion hard knocks.

On a day-to-day basis, you should not be throwing the phone in pockets with coins or keys and should use a microfiber cloth rather than abrasive fabric to clean grit away from the frame. If you purchase AppleCare+ or another form of coverage, understand that cosmetic wear is typically part of regular use and isn’t covered unless it’s accompanied by accidental damage that leads to a repair.

What Apple might switch up next to reduce scuffs

There are some unquestionable engineering levers for future runs: ensure exposed edges have slightly larger corner radii, use deeper or harder anodic layers, hybridize finishes (PVD or DLC over the top of anodizing), return to materials that don’t need dyed surface thickness to yield color. Any of those could decrease the contrast and frequency of visible scuffs in exchange for weight, heat or other unenviable properties.

By now, “Scratchgate” is less a phantom whispering campaign and more materials science fact. The iPhone 17 Pro is quick, able and expensive — but if you want to keep it looking box fresh for longer, a case isn’t optional equipment any more.