A Swedish team of researchers claims to have created an entirely new member of the E-Paper family called “Retina E-Paper” with pixels tiny enough to skyrocket reflective displays into true 4K territory (and much more), yet not forfeit daylight readability or the spectacular low-power leanness some people love those penny-‘n’-battery-saving E-Ink readers for.

Now, researchers from Uppsala University and the University of Gothenburg in Sweden say that they have developed submicron electrochromic pixels, about 560 nanometers across, that could potentially reach pixel densities as high as 25,000 per inch — an improvement by a factor of two orders of magnitude over today’s best consumer screens.

If commercialized, the technique could lead to razor-sharp e-readers, paperlike monitors and even heads-up microdisplays consuming almost no power. Initial testing allegedly indicates static images might pan out at around 0.5 mW/cm², and simple video could land as high as 1.7 mW/cm², figures that undercut most current e-paper modules and stomp all over backlit LCDs in ideal viewing conditions.

What Retina E-Paper Changes for Displays and Devices

Most smartphones run in the 300 to 500 ppi range, and top-end monochrome e-readers sit around 300 ppi. But 25,000 ppi is a whole other world — enough pixel intensity to make 4K video look pin-sharp on postage-stamp-sized displays or for text to pop when reduced down onto the surface of compact wearables and smart glasses. For comparison, a 10-inch reflector at 4K resolution is about 440 ppi; today’s e-paper can have difficulty holding contrast at those levels (especially on complex typography and fine UI).

But more than resolution, the design homes in on a key e-paper promise: ambient-light readability at extremely low power. Reflective pixels don’t spend energy on backlights, and they work in direct sun — areas where LCDs and OLEDs have to blast brightness that incinerates battery but still doesn’t deliver consistent color accuracy. The research team’s numbers suggest a path to higher resolution without torpedoing battery life, a crucial consideration for all-day readers and outdoor signage, as well as no-compromise note-taking slates.

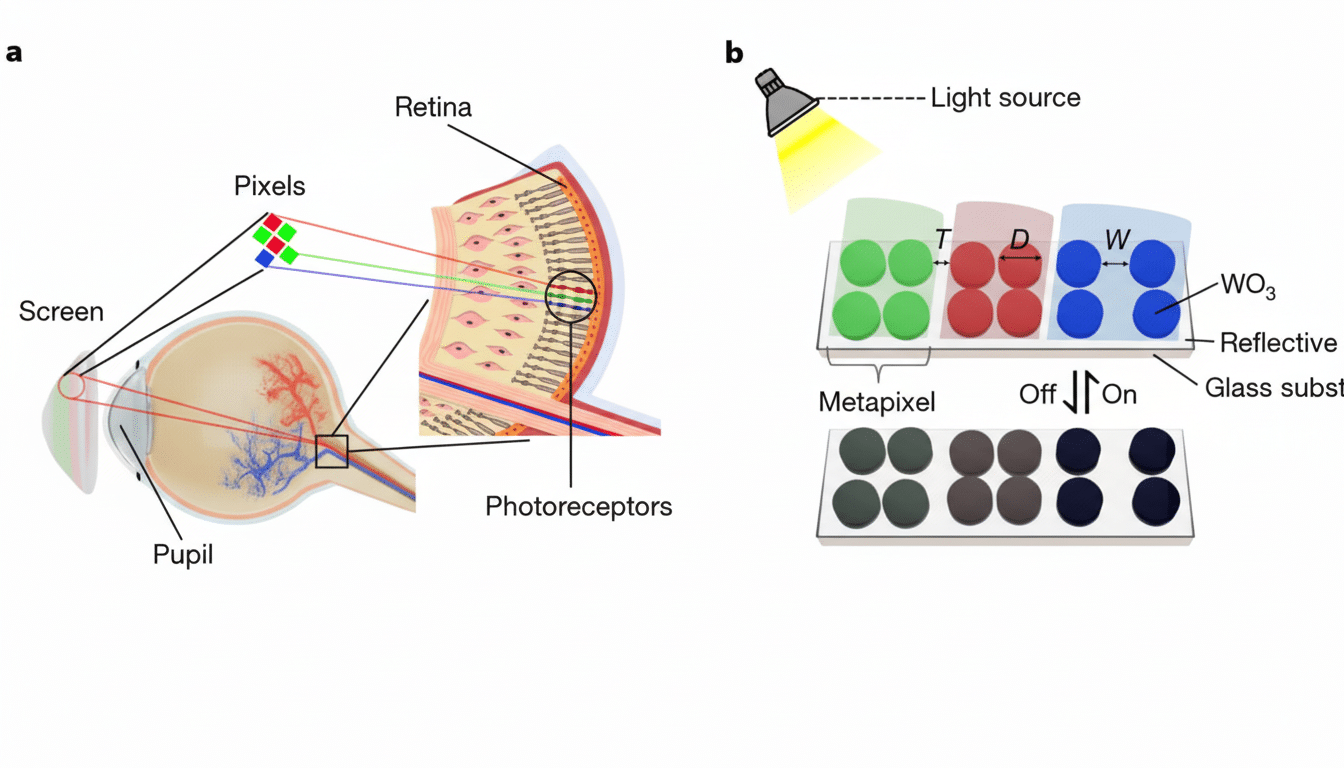

The physics behind submicron electrochromic pixels

The prototype is based on tungsten trioxide (WO₃) nanodisks, which exhibit a reversible insulator-to-metal transition upon electrical reduction. Put more simply, injecting charge changes the optical characteristics of the material such that each nanodisk becomes a controllable modulator for light. These subwavelength elements, when organized into metasurfaces, enable the display to switch reflective state quickly and with good spatial definition.

Electrochromic WO₃ is nothing new — outfits including the U.S. National Renewable Energy Laboratory have investigated its tunable optical properties for smart windows — but reducing it to pixel elements around 560 nm is what’s new.

That size is about one-tenth the diameter of micro‑OLED subpixels, and small enough to unlock vastly denser layouts while still maintaining an anti-glare, paper-like finish.

From lab prototypes to manufacturable display devices

Turning a lab sample into a consumer panel is the difficult part. The first prototypes are often patterned using tools such as electron-beam lithography, which is easy for high precision but unsuitable for mass replication. Scaling also probably will depend on nanoimprint or interference lithography and close interactions with thin-film transistor backplanes akin to what’s found in current E-Ink readers.

Handling millions of submicron pixels also requires robust drive electronics and error tolerance. Yield, uniformity and line-to-line reproducibility are long-standing challenges when scaling up from wafers to large devices. That said, display manufacturers have already figured out how to mass-produce complex TFT arrays; the issue is whether the new electrochromic layer can be deposited, patterned and driven affordably and also with a resistance to wear that consumers expect.

Color and motion are open issues. The researchers point out that this is ultimately limited to a 25 Hz refresh rate — good for still content, but so-so for, you know, watching video. Color could be obtained by stacking layers, driving them in sequence over time or using nanoscale filters — but each path comes with trade-offs for brightness, complexity or efficiency. For reference, color e-paper options today (like those from E Ink Corporation) usually cut resolution in half via the use of color filter arrays as well, and still lag behind LCDs on refresh speeds.

Where 4K-ready Retina E-Paper could make practical sense

Ultra-dense reflective pixels could disrupt several niches.

- Serif fonts, math notation and pen strokes would be displayed with near-print fidelity on high-resolution e-readers and annotation tablets.

- Papery desktop monitors — already implemented in finance, publishing and coding — could make that leap to 4K without compromising eye comfort.

- In wearables and AR, microdisplays over 10,000 ppi are a well-understood target; an alternative that’s reflective with sunlight readability lines itself up as potentially interesting to industrial helmets, outdoor navigation or low-power smart glasses.

Key caveats and a realistic development timeline ahead

This is early-stage research. Work — featured in reporting from outlets covering advanced display R&D — remains proof of concept from Uppsala University and the University of Gothenburg. With a 25 Hz refresh, monochrome-first design and manufacturing unknowns, it won’t be replacing gaming panels or HDR TVs anytime soon.

Still, the trajectory is clear. Assuming the team’s power numbers check out, and assuming that manufacturers can scale nanodisk metasurfaces to TFT backplanes at reasonable cost, “Retina E-Paper” could make possible a whole new class of 4K-and-over reflective screens. For anyone who spends hours reading or writing or working under bright light, that would not just represent a breakthrough in pixels, but in comfort and even battery life.