Federal safety regulators say SpaceX failed to properly inspect a repaired crane before it collapsed at the company’s Starbase site, issuing seven serious violations and a $115,850 fine following the incident. The Occupational Safety and Health Administration (OSHA) said its investigation remains open. SpaceX can contest the citations, and it’s not yet clear whether any workers were injured.

OSHA Cites Seven Serious Violations at SpaceX Site

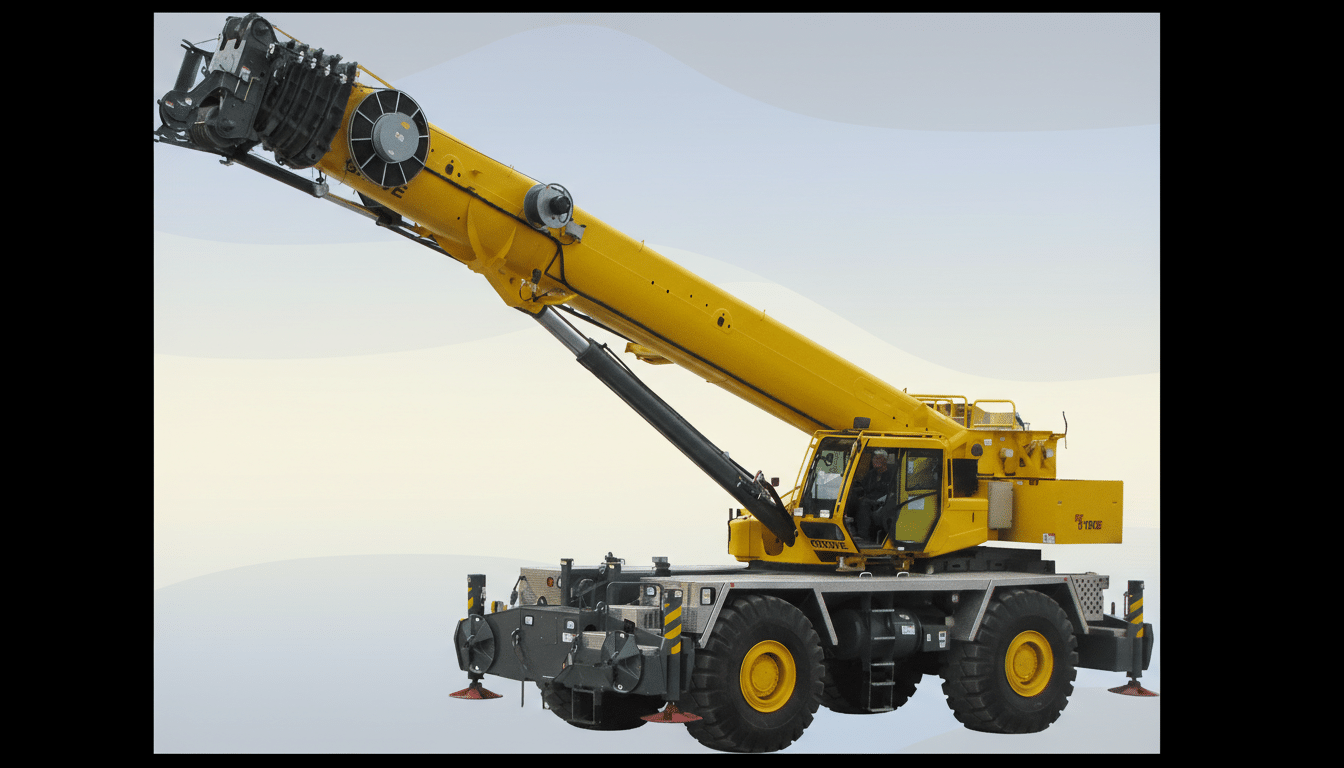

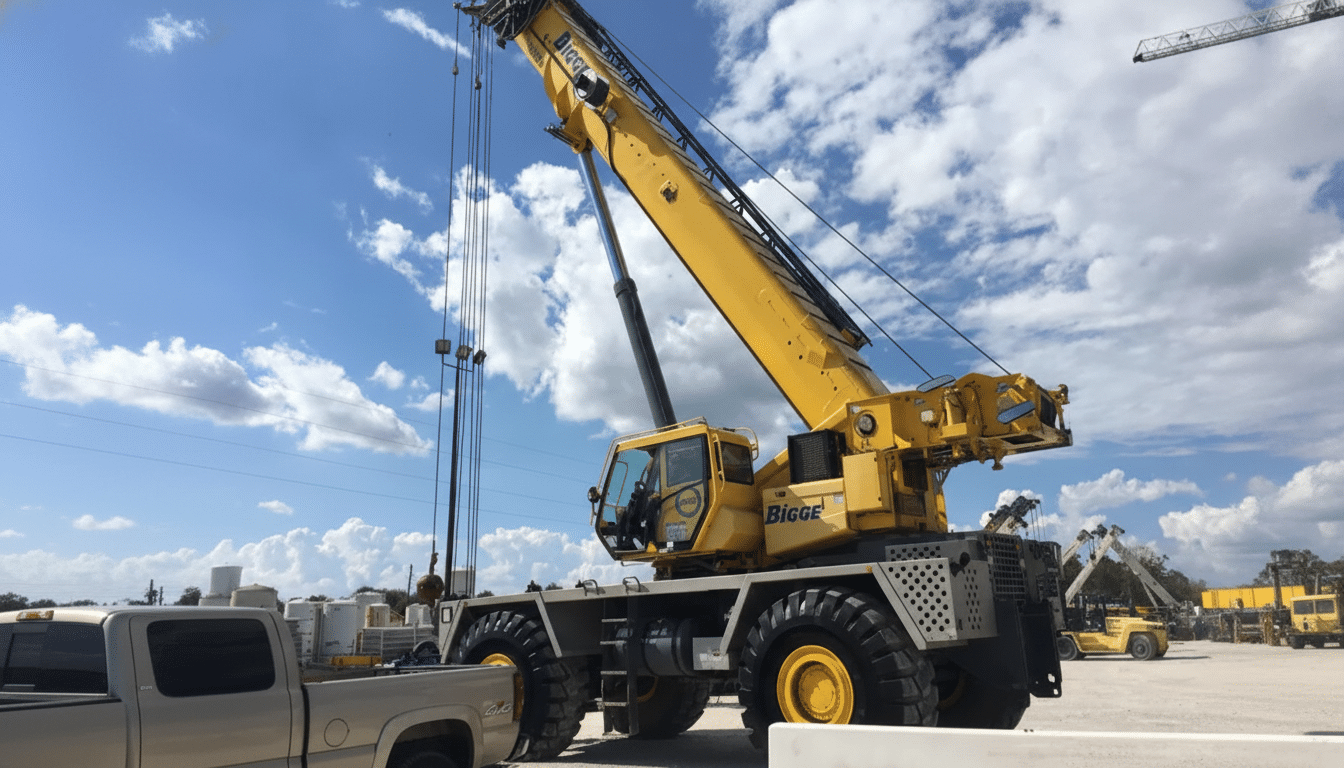

OSHA’s citations focus on inspection gaps and certification lapses. Investigators found SpaceX put a Grove RT9150E rough-terrain crane back into service after repairs without a post-repair inspection by a qualified person, as required by federal standards for cranes in construction. The agency also said the company either did not perform or could not document required monthly inspections and that no annual inspection had been recorded within the previous 12 months.

Regulators said wire ropes used during debris-handling operations did not undergo required monthly checks, and rigging gear lacked manufacturer markings that indicate safe working load—critical data for preventing overloads. OSHA added that one crane at the site had a computer that would only start after multiple attempts, a red flag given that load-moment indicators and other safety devices must be fully functional.

OSHA also found an operator running a Tadano 90-ton crawler crane with an expired certification from the National Commission for the Certification of Crane Operators. The agency issued the maximum allowable penalty on six of the seven serious violations.

Repairs and Inspections Under Increased Scrutiny

Crane standards are explicit: after any significant repair or adjustment, employers must ensure the work meets manufacturer criteria and is verified by a qualified inspector before the crane returns to duty. The Grove RT9150E, a 150-ton class machine, relies on calibrated sensors, limiters, and structural integrity assessments to stay within its load chart. If the onboard computer is unreliable or the wire rope and rigging are not verified, the margin for error narrows to zero.

That’s especially true during debris recovery. Lifting irregular Starship components can create off-center loads, side loading, and dynamic forces that exceed rated capacity. OSHA’s rules require shift, monthly, and annual inspections under 29 CFR 1926 Subpart CC, plus clear identification on rigging components. These are not paperwork exercises; they are engineered guardrails to prevent the kind of buckling seen in the collapse captured on livestreams from the site.

Launch Ambitions Raise Safety Stakes at Starbase

The incident occurred during cleanup days after a Starship test failure, when crews were moving large debris under compressed timelines. SpaceX is simultaneously expanding Starbase and preparing for a heavy launch cadence, backed by Federal Aviation Administration authorization for up to 25 Starship flights from Texas within a year. The company’s production plans call for rapidly building and turning around vehicles at industrial scale.

That pace makes the basics matter more, not less. OSHA data consistently show that lapses in inspection and operator qualification are among the leading contributors to crane accidents across construction and heavy industry. In a high-tempo test-and-repair environment, rigorous verification of repairs, documented monthly checks, and current operator certifications are the minimum thresholds for safe operations.

What Happens Next for Starbase After OSHA Findings

SpaceX has the right to contest OSHA’s findings within a short window and may seek an informal settlement or formal review. Even if penalties are reduced, abatement steps typically include tightening inspection protocols, ensuring safety devices and computers are fully functional before use, updating rigging identification, and auditing operator certifications to avoid expirations.

For regulators and industry watchers, the case underscores a broader tension between rapid aerospace development and hardline construction safety rules. As Starship operations scale, the company’s ability to demonstrate a repeatable, auditable safety system for heavy lifts—during both routine work and post-test recoveries—will be closely watched by OSHA, the FAA, and contractors across the site.

OSHA’s findings do not halt launch activity, but they add pressure to formalize the controls that make heavy-lift logistics as disciplined as propulsion or avionics. In an era where a single crane lift can make or break a tight launch window, the lesson is familiar to anyone in high-risk engineering: speed is a feature only when safety is a constant.