Jaguar Land Rover is keeping vehicle production halted into a third week as it gradually restores systems after a cyberattack, telling employees, suppliers and retail partners that the time to begin recovering from the attack will be longer than originally hoped. The company said it is in the process of a staged return to global operations, but the size and complexity of its operations will prevent assembly-line workers from returning immediately.

The decision highlights how reliant modern auto manufacturing is on enterprise IT. Those systems, along with order management, supplier scheduling, and plant tooling, are all closely interrelated; when the core systems go down, the effects spread from procurement to finished vehicle logistics.

Controlled restart and factory influence

JLR is now stressing a clean, safe restart over a rapid return, and the need for sequence—recovery of enterprise resource planning, manufacturing execution, and supplier portals—before production resumes in its UK-based and overseas plants. Though a few back-office and after-sales processes are operable manually or under constraints, the company is holding vehicle builds while data integrity and quality checks are guaranteed.

The carmaker has not specified the type of breach or identified a suspect. A conservative approach is usually taken for anything that reaches into vehicle configuration, traceability, and safety, as anything that falls out there can easily cascade into defects when lines restart.

Estimated losses and strain on suppliers

Estimates of how much money the operators stand to lose vary widely. BBC reporting has indicated weekly lost output of at least £50 million, with The Telegraph citing numbers closer to the £72 million mark. Divergence is based on assumptions about margins, the mix of high-spec models, overtime catch-up potential, and how much production can be clawed back later in the quarter.

The ripple effect is profound for the suppliers. A lot of the Tier 2 or Tier 3 suppliers have worked with very thin working capital and just-in-time contracts. Extended shutdowns halt cash flow and can drive smaller machine shops, plastics molders, and electronics suppliers toward distress — a risk highlighted by suppliers in reports cited by the BBC.

Even small pauses create backlogs, as inbound parts, paint booths, and the final inspection team in toto must be rebalanced, analysts at S&P Global Mobility said. In particular, DI catalogued how shared platforms and common components tend to amplify delays across the shifts of multiple models when one process is down.

Why a ‘controlled restart’ will take time

During normal recovery actions in such situations, response teams isolate infected networks as known-bad systems are wiped, rebuilt, or restored to predefined good states and credentials/certificates are reissued. It is not until clean system baselines have been confirmed that manufacturers reattach operational technology, revalidate the manufacturing execution system, and test everything from torque tools to vision systems.

Automakers are increasingly separating their IT networks from shop floors, but close digital ties remain for tracing products, emissions compliance checks, and software updates. It’s a coordinated set of checks to bring lines back up so that each and every VIN has the right configuration, the right quality records, and the right over-the-air software before shipping even one vehicle.

Automotive cyber risk continues to climb

Manufacturing has been one of the most frequently targeted types of businesses for ransomware, according to IBM Security data and industrial threat reports compiled by Dragos. For carmakers, the most severe costs related to hacking have nothing to do with financial loss — production stoppages are counted in days or weeks, not hours; and head-turning breach response fees look minor when manufacturers resist costly recalls of high-margin vehicles.

The UK’s National Cyber Security Centre and the US Cybersecurity and Infrastructure Security Agency have both sounded the alarm about attacks bleeding into industrial environments, urging measures as simple as multifactor authentication for remote access, offline backups with regular recovery testing, and joint IT/OT incident playbooks so plants can be brought back online in a way that doesn’t create new holes to exploit.

Customer and market implications of prolonged JLR shutdown

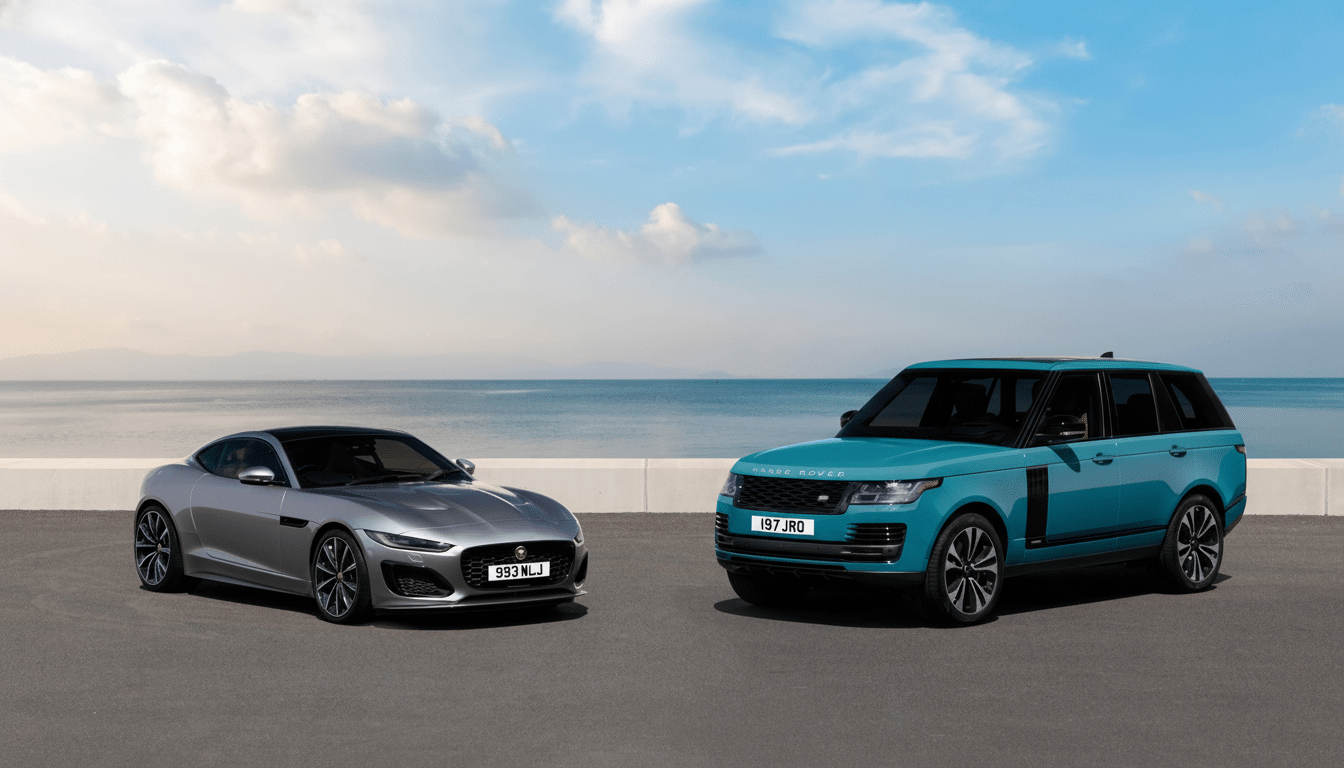

Shoppers who are waiting for the Range Rover, Defender, and various Jaguar models may also see original delivery windows pushed back. Some lost production can be recovered with overtime and extra shifts, but trim availability and supplier capacity will determine how soon the pipeline rights itself once lines restart.

The key variables for the parent company’s investors are how long production is sidelined, if production can be recovered later, and whether any launch timelines or software-defined vehicle programs get scuttled. If private information exposure is verified, notifications may proceed through regulatory bodies such as the UK’s Information Commissioner’s Office, but JLR has not revealed any of that.

What to watch next as JLR restarts systems and plants

Signs of a turnaround will be phased reopenings of some plants, getting back into supplier schedules, and restarting vehicle shipments. Supplier relief actions, like accelerated payments or smoothing order volumes, would also be indicative of stabilization throughout the ecosystem.

For now, the pause that is extending into a third week hints that JLR values rebuilding systems fully and verifying they are clean. That patience can help blunt longer-term disruption and warranty risk, even as near-term costs mount throughout the company and its supply base.