Artificial intelligence is rapidly reshaping how everyday consumer products are designed, produced, and delivered. From household appliances to nutritional supplements, factories are evolving into intelligent ecosystems where automation, robotics, and machine learning systems operate with minimal human intervention.

In 2025, the most competitive companies aren’t just manufacturing products; they’re manufacturing data, using it to optimize quality, reduce waste, and predict consumer needs with remarkable accuracy.

AI-Driven Quality Control Is Becoming the Industry Standard

Traditional quality assurance relied heavily on manual inspection, which often meant slow workflows and human error. Today, manufacturers are adopting:

- Computer vision for surface and structural inspections

- Predictive maintenance algorithms to prevent equipment failure

- Digital twins to simulate production lines before physical changes are made.

These tools enable production facilities to maintain greater consistency, especially in industries where precise formulation matters, such as food, supplements, and pharmaceuticals.

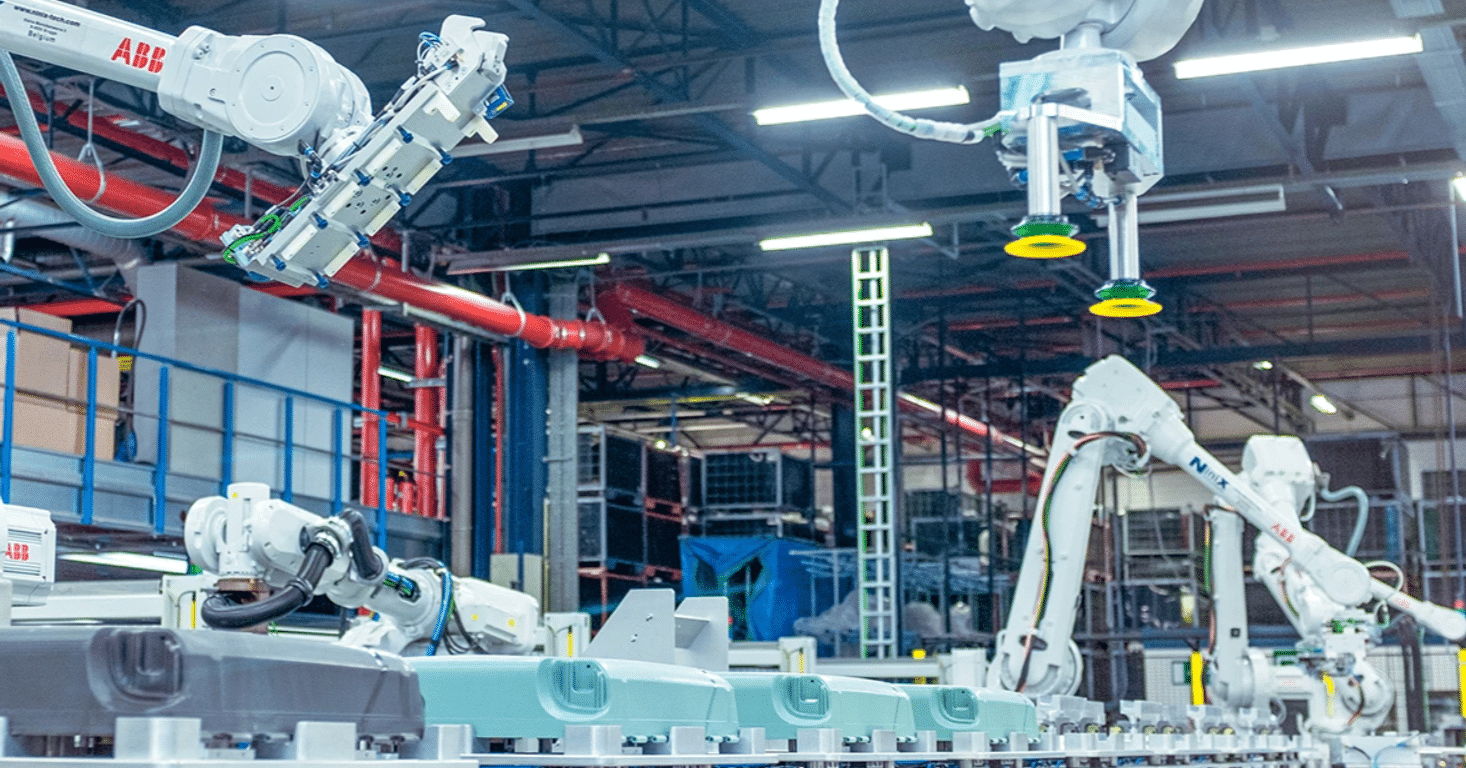

Robotics and Smart Sensors Are Creating Adaptive Factories

Modern assembly lines no longer operate on rigid schedules. IoT-connected sensors feed real-time data to AI systems that automatically adjust mixing speeds, environmental conditions, or material flow.

This adaptability dramatically reduces downtime and improves product uniformity across large manufacturing batches. Whether producing vitamins, drink mixes, or confectionery goods, automated systems allow factories to pivot to new product variations without fully reconstructing equipment.

How AI Ensures Accuracy in Infused and Functional Products

One of the most interesting applications of AI in manufacturing appears in sectors that require highly controlled dosing, such as nutritional gummies, sleep supplements, and even infused products like THC gummies.

Companies use machine-learning models, spectrometer-based scanners, and robotic dispensers to ensure each gummy contains the exact amount of active ingredients. This prevents the inconsistencies typical in earlier production methods and ensures regulatory compliance in regions where testing is required.

In other words, AI isn’t just optimizing factories; it’s directly improving product reliability and consumer safety across multiple industries.

Supply Chain AI Is Fixing Distribution Bottlenecks

Manufacturing innovation isn’t limited to the production floor. Companies are increasingly applying AI to:

- Predict raw material shortages

- Optimize shipment routes

- Anticipate seasonal demand patterns

- Adjust inventory automatically

These systems dramatically reduce costs and improve delivery times. In a global environment where delays can ripple across entire industries, predictive logistics has become one of the most valuable AI tools in the market.

Hyper-Personalized Consumer Products

As AI models become more sophisticated, manufacturers are shifting from mass production to mass customization, where individualized formulas or product specs can be created on demand.

We’re moving toward a future where consumers can order custom vitamin blends, tailored skincare formulations, or precisely dosed wellness products tailored to their biology, lifestyle, and preferences.

This personalization is only possible because of advancements in:

- Real-time factory analytics

- Automated micro-dosing systems

- AI-generated formula optimization

What once required specialized laboratories may soon be accessible through standard online ordering systems linked to smart factories.

Conclusion

AI is no longer just a competitive advantage; it’s becoming the backbone of modern manufacturing. Whether it’s improving production accuracy, enabling personalized consumer goods, or ensuring precise dosing in products. Artificial intelligence is quietly transforming nearly every category of physical goods.

We’re entering an era where products are safer, more innovative, more consistent, and increasingly tailored to the individual, and AI is the technology making it possible.