Google is exploring a rethink of how phone batteries are held in place, and the implications for repairability could be significant. A newly published filing with the United States Patent and Trademark Office describes a reinforced battery subassembly that locks into a device frame using mechanical features rather than layers of aggressive glue. The goal is to enable easier, safer battery replacements while preserving the slim profiles, water resistance, and wireless charging that premium devices demand.

How the Repair-Friendly Battery Design Works in Practice

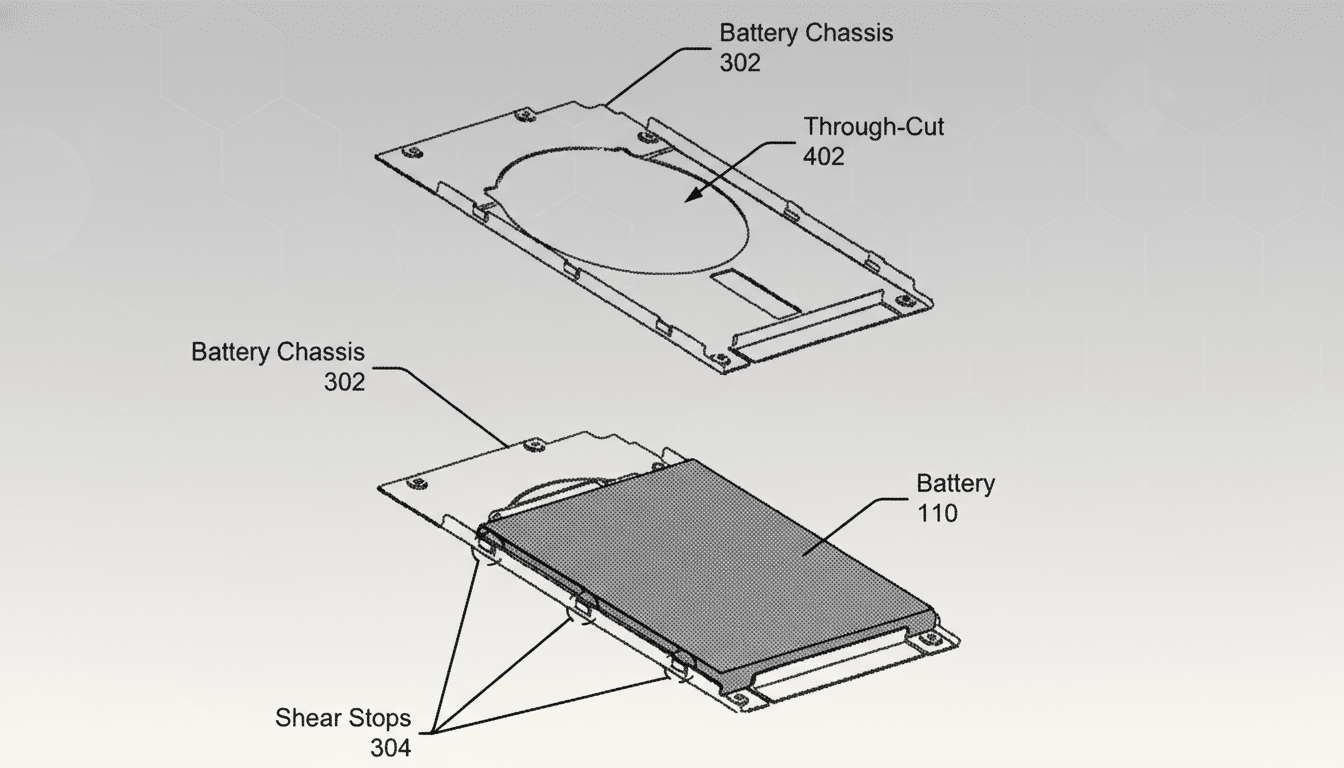

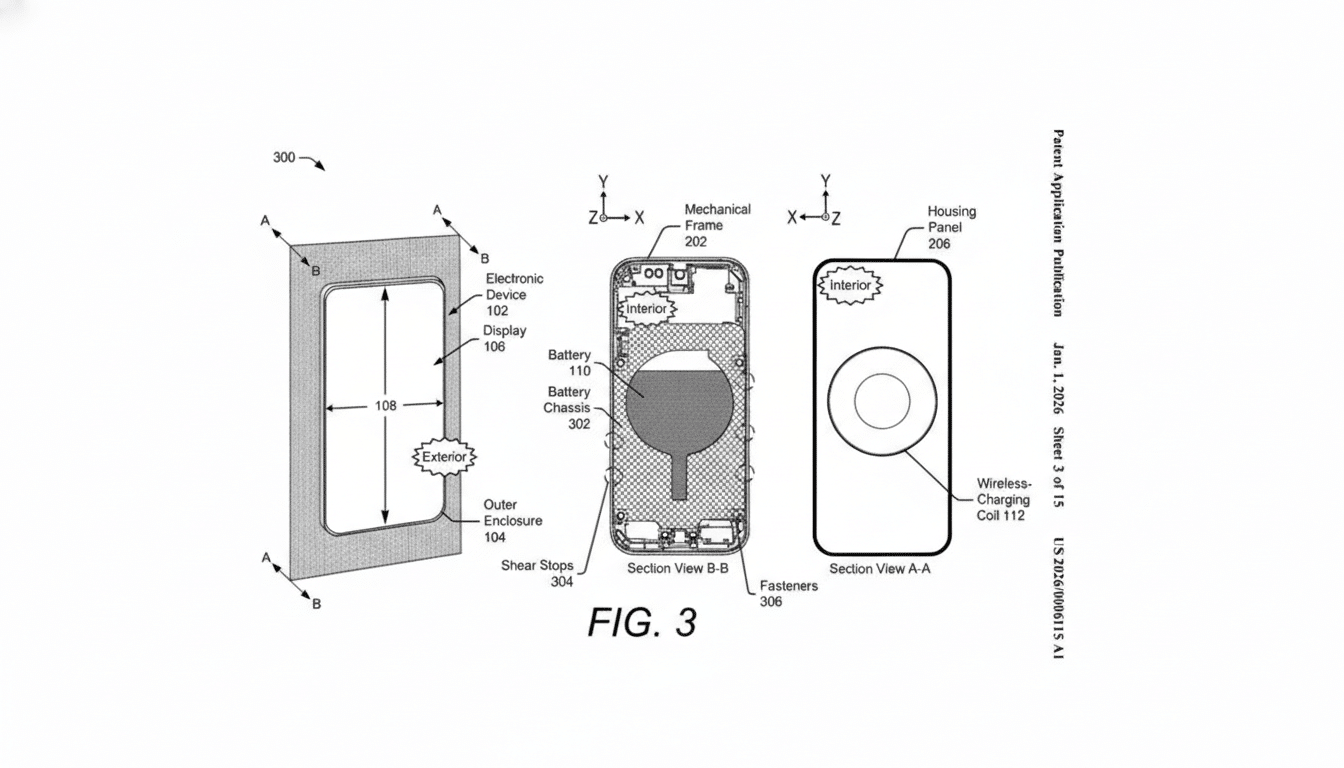

At the heart of Google’s concept is a removable battery module that sits inside a rigid metal or composite carrier. The filing outlines a “grounding” architecture with shear stops, mechanical interlocks, and guided load paths that secure the pack and distribute stress. In practice, this means that if the device twists, flexes, or experiences an impact, the structural frame absorbs most of the energy instead of the battery pouch itself.

Unlike the snap-off backs of early smartphones, this approach doesn’t turn modern devices into swappable-battery gadgets. The module remains captive inside the chassis, but it can be unlocked and lifted out during a repair without wrestling with heat guns, solvents, or fragile pull tabs. That reduces the chance of puncturing a lithium cell—a leading risk in battery service work—and cuts down on the adhesive cleanup that slows technicians.

The filing also makes clear that the design respects contemporary constraints: wireless charging coils and magnets need precise alignment, and water resistance depends on reliable compression seals. A rigid carrier can provide fixed reference points for those elements in ways that glue cannot, potentially improving both assembly consistency and serviceability.

Why It Matters For Repairability And Safety

Adhesive-heavy battery installs are one of the biggest barriers to mainstream device repair. iFixit and independent service shops routinely document how heat, alcohol, and patient tugging are needed to loosen packs from thin frames. When batteries swell with age or heat, the glue can lock them in place even more stubbornly. By relying on mechanical retention, Google’s concept could shorten bench time, reduce failures, and make routine battery swaps more predictable.

There’s also a safety angle. A well-designed carrier that defines safe pry points and load paths lowers the chance that a spudger slips or a pack creases under uneven force. For large-screen devices and foldables—where internal packaging is tight and layered—the benefits could be even greater. The approach scales to tablets, laptops, and wearables too, according to the application’s examples.

Shifting Policy and Market Pressures on Device Repair

Right-to-repair momentum is reshaping design incentives. The European Union’s Batteries Regulation calls for portable devices to allow easy battery removal and replacement by end users or independent shops, pushing manufacturers to rethink adhesive-heavy assemblies. In the United States, states including California and Oregon have enacted repair laws that require access to parts, tools, and documentation, and regulators are increasingly scrutinizing practices that hinder service.

Some brands have moved incrementally—adding stretch-release adhesives, larger pull tabs, or internal frames that partially constrain batteries. Others, like Fairphone, prove that modules with minimal glue can coexist with water resistance, even if it’s not the highest IP rating in the industry. Google’s concept suggests a more systematic answer: using engineered interlocks to meet durability and ingress protection targets while ditching most of the glue.

Engineering Trade-offs and Opportunities in Battery Design

Mechanical retention isn’t a free lunch. Frames add parts and a few grams, and they must be designed around antenna placement, thermal paths, and the stack-up of coils, shields, and magnets that enable wireless charging. But the payoffs are compelling: predictable assembly torque, repeatable gasket compression for water resistance, and known service access points that reduce labor and scrap. In high-volume manufacturing, fewer messy adhesive steps can also cut cycle times and improve quality control.

For foldables, where hinge-induced flex is a latent threat, a carrier that spreads shear loads could be the difference between a long-lived battery and one that degrades prematurely. For laptops and tablets, where large cells cover broad areas, localized impacts are less likely to translate into dangerous creases if the pack is mechanically isolated from the outer shell.

What It Could Mean for Future Google Pixel Devices

Google has steadily expanded its authorized parts program and made recent Pixels more straightforward to service than earlier models, but battery extraction remains the trickiest step in many modern phones. A shift to a lock-in battery subassembly could reduce repair complexity and support longer device lifespans—goals aligned with sustainability commitments and with independent assessments that link longer use cycles to lower environmental impact.

As always, a patent filing is a statement of intent, not a product roadmap. Yet it signals that Google is approaching repairability as a design constraint rather than an afterthought. If this architecture lands in upcoming phones, tablets, or foldables, it would mark a meaningful advance: less glue, fewer risks, and a path to practical battery replacements without giving up the slim, sealed builds consumers expect.