Amazon has stopped work on Blue Jay, a multi-armed warehouse robot introduced to speed sorting and movement of parcels in same-day delivery sites, ending the pilot in under six months and shifting its team and core technology to other automation efforts.

The decision underscores an uncomfortable reality in advanced logistics: even the world’s most automated retailer will walk away from a promising concept when the economics, reliability, or integration complexity do not clear internal bars. Amazon said the learnings from Blue Jay will inform other “manipulation programs,” signaling a pivot rather than a retreat from robotic handling.

- Inside Blue Jay’s Design and Its Same-Day Objectives

- Why Amazon Pulled the Plug on Blue Jay So Quickly

- Technology Will Live On Inside Other Robots

- What Blue Jay’s End Means for Same-Day Fulfillment Economics

- Amazon’s Robotics Strategy Remains Intact After Blue Jay

- What to Watch Next in Amazon’s Warehouse Robotics Push

Inside Blue Jay’s Design and Its Same-Day Objectives

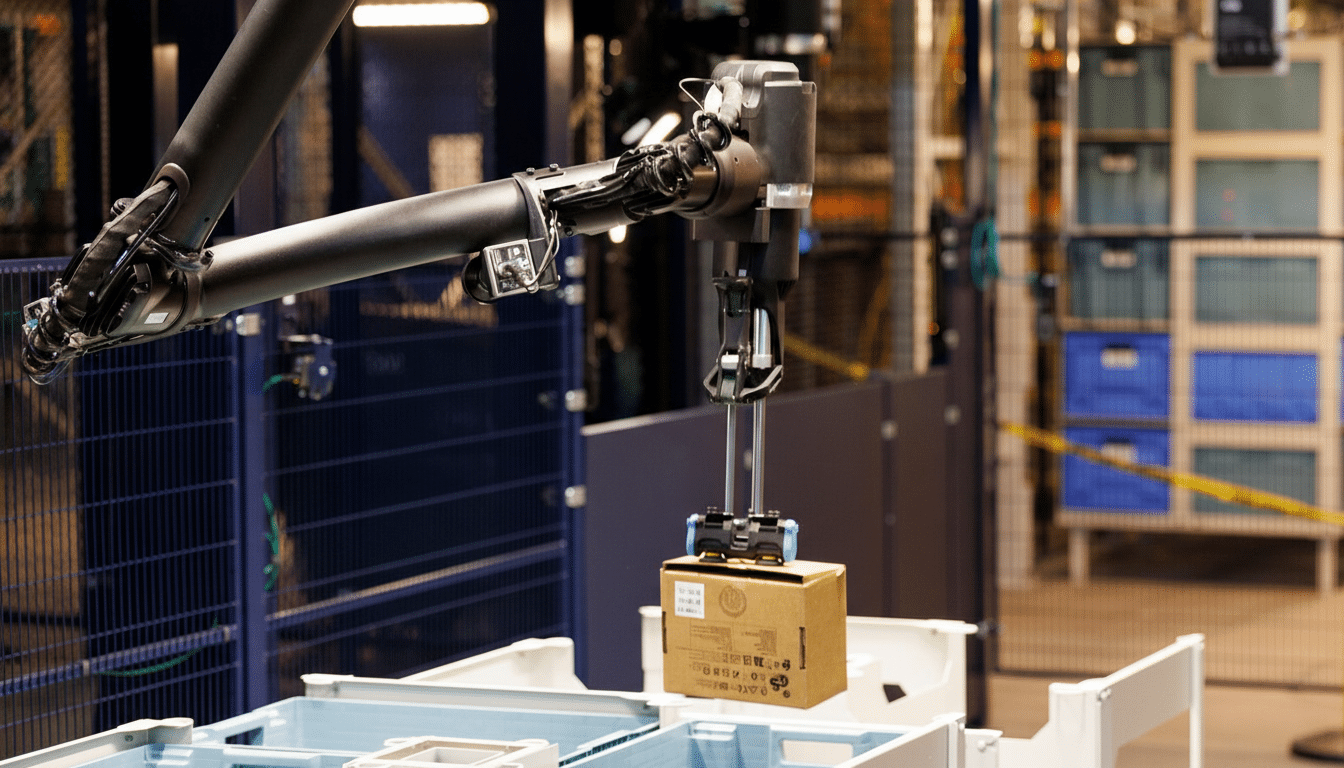

Blue Jay was designed for the chaotic heart of same-day operations, where a mix of customer returns, oddly shaped packages, and rush orders collide. The robot’s multi-armed configuration aimed to grab, orient, and place parcels across chutes and conveyors with minimal human intervention, reducing touches in a notoriously labor- and exception-heavy workflow.

Amazon highlighted that Blue Jay moved from concept to deployment unusually fast, crediting AI-driven simulation and perception models for compressing development cycles. In practice, that likely meant accelerated training of vision systems, grasp planning for deformable packages, and policy learning to handle edge cases without pausing the line.

Early trials reportedly ran in a same-day facility in South Carolina, where throughput, exception rates, and uptime would have been scrutinized alongside safety metrics. In dense, fast-turn buildings, even small delays ripple across the network; robots that cannot sustain steady cycle times under real volume and SKU variability are quickly sidelined.

Why Amazon Pulled the Plug on Blue Jay So Quickly

Insiders across warehouse automation point to four recurring friction points that often end pilots prematurely: exception handling, reliability under shift-length duty cycles, integration overhead with legacy software and conveyance, and safety certification at scale. Any one of these can push payback beyond acceptable windows.

Same-day sites are an especially harsh proving ground. Packages arrive with torn labels, slick shrink-wrap, and irregular shapes; the mix changes hour by hour. AI perception systems have improved, but the “long tail” of oddities drives manual interventions. If a robot’s exception rate forces frequent human assists, the labor savings evaporate.

Total cost of ownership also matters. Beyond the unit price, operators model maintenance, spare parts, technician hours, and the cost of downtime. Industry groups such as MHI and WERC have noted in recent surveys that many automation pilots fail to scale not because they never worked, but because they did not work predictably enough in real distribution centers.

Technology Will Live On Inside Other Robots

Amazon says Blue Jay’s underlying grasping, perception, and motion-planning technology will migrate to other systems. That likely includes programs focused on tote-to-shelf manipulation, singulation, and case handling—areas where consistent packaging reduces edge cases and improves ROI.

The company has already showcased Vulcan, a two-armed system built for storage compartments that combines rearranging with camera-guided suction picking. Vulcan’s tactile feedback and data trained on real interactions are the kind of ingredients Blue Jay’s team can augment, improving reliability without starting from scratch.

Reassigning Blue Jay’s engineers to adjacent projects keeps hard-won domain knowledge—about failure modes, gripper design, and human-robot workflows—inside the building. That continuity often speeds the next iteration far more than launching a fresh research effort.

What Blue Jay’s End Means for Same-Day Fulfillment Economics

Same-day fulfillment compresses labor, transportation, and inventory decisions into razor-thin windows. Automation can help, but only if it sustains throughput during peaks while handling messy real-world variation. Operations researchers often describe the trade-off as a three-way balance between speed, accuracy, and flexibility; in same-day, the acceptable tolerance bands are narrow.

Safety and ergonomics remain powerful drivers. Warehousing continues to show above-average injury rates, according to government labor data. Even if a specific robot falls short of productivity goals, the underlying manipulation tech can still reduce strain or remove workers from repetitive lifts when embedded in the right station design.

Amazon’s Robotics Strategy Remains Intact After Blue Jay

Amazon’s automation strategy has always mixed big bets with fast kill-switches. Since acquiring Kiva Systems more than a decade ago, the company has layered mobile robotics, automated storage, and piece handling into its network, now operating an installed base of robots that numbers well into the hundreds of thousands.

Organizations like the International Federation of Robotics note that logistics-focused service robots are among the fastest-growing categories globally. That momentum, coupled with continuing advances in vision and foundation models, suggests Amazon will keep pushing manipulation into new workflows—just not with Blue Jay in its original form.

What to Watch Next in Amazon’s Warehouse Robotics Push

Analysts will watch for signs that Blue Jay’s software stack shows up in other stations, broader pilots of Vulcan, and shifts in Amazon’s capital spending mix toward proven workcells over greenfield concepts. Hiring patterns inside Amazon Robotics and references to “manipulation” in earnings commentary are also useful leading indicators.

The short life of Blue Jay is not a verdict on warehouse robots; it’s a reminder that in high-velocity logistics, the bar for reliability and ROI is unforgiving. The next generation will arrive quickly—and it will carry Blue Jay’s lessons in its code.